E2G is focused on delivering innovation and new technologies that will help the industry move forward towards safer and more reliable facilities. Today is no exception. In the latest issue of the Inspectioneering Journal, David A. Osage contributed an article highlighting E2G’s new inspection scheduling methodology that will reshape asset integrity and equipment lifecycle planning and management.

Using his vast knowledge and expertise in fitness for service (FFS), David outlines how E2G’s groundbreaking new maximum allowable working pressure (MAWP) approach aligns with API 579-1ASME FFS-1 standards, ensures integrity with continued operation, and works with the damage classes listed in API 579.

Consequences of Unanticipated Damage

Typical inspection results outline anticipated damage or unanticipated damage. We know that anticipated damage is corrosion. According to API 579-1/ASME FFS-1, owner-users can continue operations with known damage if the location and type are properly managed and if the damage is under the corrosion rate, or the corrosion allowance put into the design. However, unanticipated damage (e.g., blistering, cracks, or pitting) requires plant personnel to take a step back. They need to identify the damage mechanism, determine what caused the damage, and conduct an FFS assessment to make run, repair, or replace decisions. If run or repair is deemed to be an acceptable option, then the equipment should be run at MAWP or a reduced MAWP.

E2G’s MAWP Approach

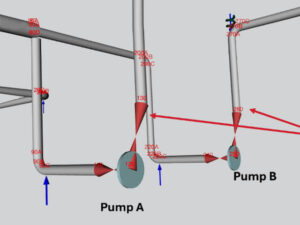

Using our expertise in FFS, E2G’s MAWP approach is a general approach that works for all damage classes and components. Using this approach, we manage the MAWP at temperature versus time – that’s the management factor. MAWP versus temperature versus time provides data that management can use to make run decisions.

“Our clients repeatedly ask us, ‘At what pressure and coincident temperature and for how long can I safely operate per jurisdictional requirements?’ It’s all about pressure, temperature, safety, and how long the equipment will run. DMLs are the only way to answer this fundamental question.”

David A. Osage, President & CEO, E2G | The Equity Engineering Group, Inc.

E2G’s damage management location (DML) workflow, available exclusively in PlantManager PILOT™, uses MAWP to determine inspection schedules from fitness-for-service (FFS) assessment results, inspection data, and condition monitoring locations (CML) data to proactively manage risk and optimize equipment performance. PlantManager PILOT automates and guides the appropriate damage data collection and seamlessly incorporates FFS calculations to support informed engineering decisions as well as delivers a complete view of the components for accurate inspection planning. E2G’s new methodology will help facilities effectively extend asset life, minimize unplanned shutdowns, and improve overall safety and reliability across industrial facilities.

Comprehensive IDMS Software

Across the industry, commercially available inspection data management systems (IDMS) and asset integrity management systems (AIMS) both lack the construction code and FFS calculation capabilities to implement

the MAWP Approach required for inspection scheduling. PlantManager PILOT is the only cloud-native platform that provides end-to-end asset lifecycle management capabilities by managing inspection activities, recording DMLs, and calculating fully quantitative API 581 risk assessments for inspection optimization.

Contact E²G to learn more about PlantManager PILOT, the MAWP approach, and how to apply DMLs to your company’s asset integrity management strategy.