- Home

- Engineering

- Mechanical & Structural Engineering

- Turnaround Planning & Support

TURNAROUND PLANNING & SUPPORT

Are you Ready for Your Next Turnaround?

Did you know 66% of turnarounds (TARs) finish late and overrun budget by 10% or more?

As one of the most significant portions of a plant’s yearly maintenance budget, TARs are a significant risk to the bottom line that is directly related to the level of readiness. While operations plan for the loss of production during the outage, the potential for lengthening the shutdown window is very high.

A successful TAR requires project scope management, minimum schedule delays, controlled costs, and transparent communication.

Equity offers in-person or virtual support to help you make fast, informed decisions before or during the scheduled shutdown to help you make the right decisions at the right time to maximize your return.

Invest in the reliability and future performance of your site's assets with a properly executed turnaround.

Proactive Turnaround Support

TARs are an investment in the reliability and future performance of your site’s assets – implementing a three-step strategy will help you plan and execute a successful TAR. Equity’s proactive TAR support helps you deliver a TAR on-time and on budget, plus improve equipment reliability and reduce operational risks.

| Pre-Turnaround Planning | Turnaround Execution | Post-Turnaround Planning |

|---|---|---|

| Begin TAR planning several years before the scheduled shutdown to minimize unplanned work scope and reduce overall downtime. | Onsite or virtual TAR support will improve communication, control project costs, and reduce schedule delays. | Increase the effectiveness of future TARs by summarizing the findings and reviewing recommendations and follow-up actions. |

Available services:

|

Available services:

|

Available services:

|

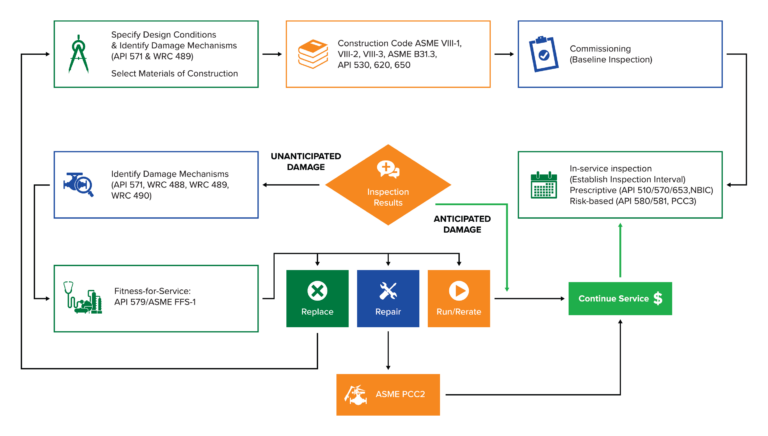

FFS assessments are applicable before and during a shutdown. Equity recommends conducting proactive FFS assessments to support an efficient and effective TAR.

Proactive FFS

Review the results of detailed remaining life evaluations, rigorous engineering evaluations, and damage mechanism reviews to streamline TAR planning.

The benefits of a proactive FFS assessment are:

- Extend equipment life and optimize inspection intervals and inspection tasks

- Understand the effects of and potential for future damage progression

- Establish screening tools to aid in NDE and flaw sizing exercises

Reactive FFS

During the shutdown, conduct an FFS assessment when flaws or damage are discovered during equipment shutdown inspections or on-stream inspections.

The benefits of a reactive FFS assessment are:

- Make informed run, repair, or replace decisions during the shutdown

Implement an RBI program at least two years before a TAR to strategically plan inspection activities, maintain equipment reliability, and control costs.

- Pre-TAR Planning – we will help you develop a solid inspection plan to perform quality assurance checks, identify issues, and collaborate with our multi-disciplinary team.

- Post-TAR – we will update your RBI program on a short- or long-term basis to maintain its integrity and validity.

Support TAR planning and shutdown strategies with clearly defined IOWs and CCDs at your facility. Our team will develop thorough CCDs and customized IOWs for each process unit by analyzing your equipment’s specific operation, stream chemistry, and metallurgy to minimize the likelihood of damage.

At Equity, our team works with you to detect active and potential damage mechanisms, set safe operating limits, and develop long-term risk management plans. The DMR provides practical recommendations to maximize production, extend the safe operating life, and minimize costly component failures and unit downtime.

Recommended Reading

- Fitness-for-Service (FFS) /

- Industry Insights Articles /

- Mechanical & Structural Engineering /

- Turnarounds /

- Industry Insights /

- Library /

- Mechanical & Structural Engineering /

- Turnarounds /

- Library /

- Risk-Based Inspection (RBI) /

- CCDs & IOWs /

- Library /

- Materials & Corrosion /

- Fitness-for-Service (FFS) /

- Industry Insights /

- Library /

- Mechanical & Structural Engineering /

- Risk-Based Inspection (RBI) /

- Turnarounds /

- Fitness-for-Service (FFS) /

- Industry Insights /

- Library /

- Mechanical & Structural Engineering /

- Risk-Based Inspection (RBI) /

- Turnarounds /

- Damage Mechanisms /

- Fitness-for-Service (FFS) /

- Industry Insights Articles /

- Mechanical & Structural Engineering /

- Pressure Vessels /

- Risk-Based Inspection (RBI) /

- Turnarounds /

- Weld Repairs /

Turnaround Support Expertise

Our mechanical and structural engineering team has extensive experience with inspection, evaluation, repairs, and remaining life assessments for equipment. As pioneers of FFS technologies and lead investigators on many international standards, our team combines their extensive experience with state-of-the-art technology to help extend the lifecycle of your existing assets and create safe operating environments.

Our experts:

- Have 200+ years of combined field experience

- Pioneered development of FFS

- Are the primary authors on WRC 528 and WRC 562

- Serve as the lead investigators on API 579 and API 571

- Provide emergency onsite support within 24 hours