- Home

- Engineering

- Rotating Machinery & Vibration

- Two-Phase Flow Vibration

TWO-PHASE FLOW VIBRATION

Risk Mitigation Solutions for Piping Systems

In process facilities, two-phase flow creates a significant challenge for piping systems, including failures from fatigue. The difference in density and velocity between phases can generate substantial dynamic forces, leading to severe piping vibration. This phenomenon is a common cause of fatigue failure and poses a direct risk to operational safety and plant reliability.

Unfortunately, standard vibration assessments often fail to capture the complex, intermittent nature of two-phase flow dynamics, particularly in high-temperature systems where thermal expansion limits the effectiveness of conventional restraints.

Equity Engineering offers specialized consulting services to diagnose, analyze, and resolve vibration issues, ensuring the long-term reliability and safety of equipment and piping systems.

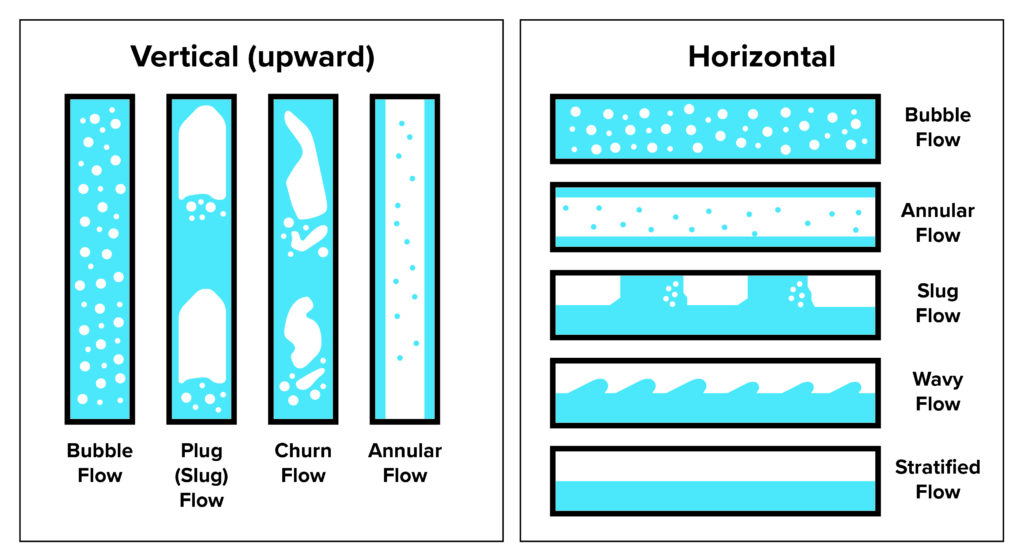

What Are Two-Phase Flow Regimes?

Understanding the specific flow regime within your piping system is key to understanding and diagnosing vibration issues. Two-phase flow regimes are directly related to the process conditions and the layout of the piping.

- Vertical (upward) – gravity works against the flow direction, which results in different flow patterns and set of challenges.

- Horizontal – gravity acts perpendicular to the flow direction, which causes the heavier liquid to settle at the bottom of the pipe. As velocity increases, the regime shifts and can escalate the potential for vibration.

Piping Vibration Analysis

Our team delivers practical recommendations to improve safety and increase equipment reliability through a multi-disciplinary vibration analysis methodology.

- Advanced Diagnostic Analysis: We use advanced statistical methods to assess the non-Gaussian, intermittent loads typical of slug and plug flow regimes. This approach provides a more accurate representation of fatigue risk compared to conventional vibration RMS measurements alone.

- Fitness-for-Service (FFS) Assessment: Leveraging API 579, we conduct a thorough evaluation of piping stress levels. Through a combination of Level 1, 2, and 3 assessments, we determine if the measured vibration could lead to fatigue failure and offer practical and informed recommendations.

- Root Cause Analysis: We identify the fundamental mechanisms causing vibration. By analyzing flow rates, pipe orientation, fluid properties, and system geometry, we determine whether the vibration stems from turbulence-induced random forces or high-impact intermittent flow events.

- Mitigation Strategies: We provide customized recommendations that range from the design of optimized piping supports to process modifications aimed at altering the flow regime and reducing harmful dynamic forces at their source.

Benefits of Equity Engineering’s Vibration Analysis

Our specialized consulting services provide you with practical recommendations to manage risk and maximize equipment availability.

- Prevent Catastrophic Failures: Proactively identify and resolve high-risk vibration to prevent costly piping failures, environmental incidents, and unplanned shutdowns.

- Enhance Asset Reliability: Increase the operational lifespan and performance of critical piping systems, heat exchangers, and connected equipment.

- Improve Operational Safety: Mitigate risks to personnel and the facility by ensuring the structural integrity of your process piping is maintained.

- Optimize Maintenance Expenditures: Transition from a reactive repair cycle to a proactive integrity management strategy, reducing long-term maintenance costs and controlling budgets.

Your Vibration Analysis Experts

Safely operating your equipment is essential. You need to be confident in the long-term reliability of all your assets. Our dedicated team delivers specialized consulting services and technology to help you solve your most difficult vibration challenges.

Contact Equity Engineering to Discuss Your Vibration Challenges.