- Home

- Engineering

- Mechanical & Structural Engineering

- Structural Integrity

STRUCTURAL INTEGRITY

Understand How Structural Systems Behave & Interact

Did you know poor infrastructure conditions and failures cost U.S. businesses more than $130 billion per year? This economic hit includes more than just repair and replacement costs; business delays and interruptions make up more than one-third of those costs. The repercussions of poor infrastructure or unstable structures are both massive and expensive.

Equity understands how structural systems behave and interact and can provide practical recommendations to improve business continuity, prevent loss of containment, and increase operational reliability at oil and gas, chemical, petrochemical, and other industrial processing facilities.

Equity’s structural integrity services can support:

- Large scale projects

- Code compliance checks

- Turnaround (TAR) planning and support

- Design of review third-party designs

"Maintaining the integrity of structures and foundations supporting equipment and piping in your facility may be critical for the safe & continued operation of your equipment."

Typical Structural Integrity Challenges

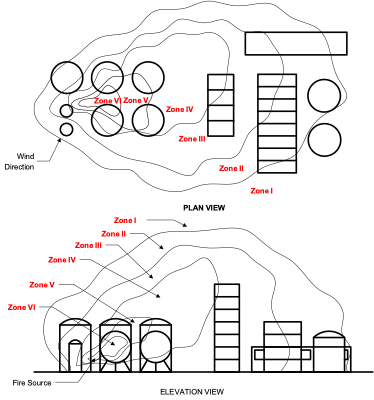

Structure and foundation problems are a result of design deficiencies, construction defects, deteriorating conditions, extreme environmental events, and changes to loads. Equity engineers have years of experience in evaluating a wide variety of damage to plant structures, including:

- Corrosion issues

- Structural member collapse

- Wind and seismic effects

- Fire damage

- Global and localized buckling

Equity's Structural Integrity Assessment Services

Equity’s innovative structural design and integrity assessments help optimize equipment availability, make repair-replace decisions that ensure stability and continued safety, improve performance, and avoid unnecessary repairs or replacements.

Equity’s assessment services include:

- Evaluation of steel or concrete support structures and foundations with local or widespread damage

- Stability evaluations to determine risk of collapse

- Fire damage assessment

- Wind and seismic capacity evaluation

- Increased load evaluation, including unanticipated hydrostatic load

- Evaluation of wind-induced and mechanical vibration in stacks, heaters, and process towers

- Modification design to mitigate vibration

- Design structural modifications for recommended pipe support changes, support elements, and attached structures (brace pipe racks, new frames, other modifications)

A sound structural integrity program will improve safety, facility reliability, and environmental performance.

Conduct on-site piping and structural vibration surveys and testing to evaluate the equipment, assess the risk of vibration, and provide recommendations to mitigate vibration fatigue failures.

- Reactive – if you notice a pipe or supporting structure moving under normal operating conditions, we will diagnose, evaluate, and mitigate any failure risks.

- Proactive – if your facility is changing processing fluid or lengthening pipes, we will conduct a piping or vibration survey to help you understand how those changes will affect the fluid flow and frequencies in the piping.

Structural integrity should address all aspects of the lifecycle of a structure from design to retirement. A rigorous asset integrity management program that includes structural integrity will ensure equipment is designed, constructed, installed, operated, and maintained properly to prevent the loss of containment and to improve operational safety and reliability.

Structural Integrity Risk Assessments

Assessing the inspection and maintenance program for the foundations and frame structures supporting vessels and heat exchangers, tower and drum pedestals, pipe racks, and rotating equipment support structures at your facility will reduce risk and improve operational safety. Equity will rank your critical structures with our risk assessment process and help focus resources to the structures with the greatest risk.

Recommended Reading

- Industry Insights /

- Library /

- Mechanical & Structural Engineering /

- Risk-Based Inspection (RBI) /

- Structural Integrity /

- Fitness-for-Service (FFS) /

- Industry Insights /

- Library /

- Mechanical & Structural Engineering /

- Structural Engineering /

- Tanks /

- Industry Insights /

- Library /

- Mechanical Integrity /

- Structural Integrity /

Structural Engineering Expertise

Our mechanical and structural engineering team blends experience with multiple industry standards to provide the best solutions for structural deficiencies or damage. We focus on asset management best practices to prevent failure in future designs or in existing equipment.

Our experts:

- Have 200+ years of combined field experience

- Pioneered development of FFS

- Are the primary authors on WRC 528 and WRC 562

- Serve as lead investigators on API 579 and API 571

- Provide emergency onsite support within 24 hours