Equity Technical Institute (ETI) offers specialized training courses for personnel in the oil and gas, petrochemical, chemical, and other industrial processing industries. You will learn from a team of highly skilled and knowledgeable engineers who have 20+ years of industry experience.

ETI training courses focus on areas of mechanical integrity, pressure equipment, instrumentation and process control, materials and corrosion, piping vibration, welding, risk management, and Equity software. These industry-relevant training courses follow the same high-quality development as our API-U courses.

All courses can be customized to meet your organization’s training needs and qualify as activities for API’s CPD requirements.

On-Demand Learning Now Available!

Discover the convenience and flexibility of ETI’s on-demand training courses. These bite-sized lessons are prepared by Equity SMEs and enable you to gain valuable professional knowledge at your own pace.

Request Custom Training or Receive More Info on our Courses

Choose Your Preferred Learning Style

Hybrid

Most scheduled courses are offered in a hybrid format, allowing you to choose whether to learn virtually or attend in-person.

Virtual

Virtual courses are designed to maximize learning in an online environment and are a maximum of four hours per day.

On-Site

Equity instructors will travel to your office or plant. All courses can be customized to meet your specific requirements.

On-Demand

You can access our expertly crafted courses at your own pace, on your own schedule, and from anywhere.

Upcoming Training Courses

Achieving Mechanical Integrity Excellence in Crude Units

Achieving long-term reliability in refinery crude units requires more than just routine inspection—it demands a deep understanding of the processes, materials, and operating conditions that drive mechanical integrity (MI) excellence. […]

Achieving Mechanical Integrity Excellence in Hydroprocessing Units

Achieving reliable, predictable performance in hydroprocessing (HP) units requires more than basic familiarity with equipment—it demands a clear understanding of how process conditions, materials, and operating practices interact to drive […]

Achieving Mechanical Integrity Excellence in Fluid Catalytic Cracking Units

Mechanical integrity (MI) in fluid catalytic cracking units (FCCUs) is challenged by complex process conditions, high temperatures, and a diverse range of damage mechanisms (DMs)—but these challenges can be managed […]

Welding for Mechanical Integrity Professionals

Welding plays a critical role in the integrity and long-term reliability of pressure equipment and piping, and understanding its fundamentals is essential for anyone supporting mechanical integrity (MI) programs. This […]

Corrosion Under Insulation: Finding, Assessing, and Preventing Damage

Corrosion under insulation (CUI) remains one of the most costly and persistent challenges to fixed equipment mechanical integrity (MI)—but it doesn’t have to be. This course gives participants the practical […]

Fixed Equipment Mechanical Integrity Programs

This course delivers a powerful introduction to fixed equipment mechanical integrity (FEMI) by showing how past industrial events shaped the modern standards that protect people, facilities, and production today. Participants […]

Pressure Vessels: ASME VIII-1

Gain a solid, practical understanding of pressure vessel design with this in-depth training course, focused on the requirements of the ASME Boiler & Pressure Vessel Code, Section VIII, Division 1 […]

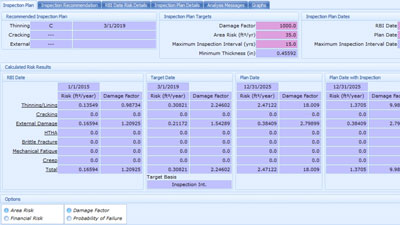

PlantManager SAGE with FFS Applications

This PlantManager SAGE training course provides training specific to the PlantManager SAGE suite of analytical tools used to evaluate pressure-containing equipment such as process vessels, piping, and storage tanks. The […]

Bolted Flanged Joint Integrity: Design, Evaluation, and Optimization

Achieving leak-free performance in bolted flanged joints (BFJs) requires more than just tightening bolts—it demands a solid understanding of the mechanics, design rules, and assembly practices behind every BFJ. This […]

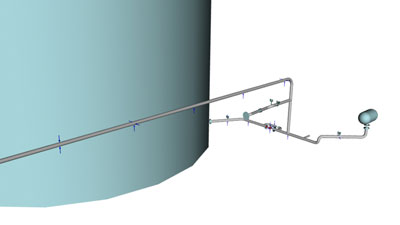

Storage Tanks

Learn the essential knowledge needed for effective welded storage tank design and analysis with this comprehensive course. Focused on the key requirements of API 650, this course equips attendees with […]

Piping Vibration

This course combines a rigorous technical overview of measurement and severity analysis of piping vibration from the perspective of plant engineers that are interested in identifying if a problem actually […]

Repair Strategies

Discover the full potential of pressure equipment and piping repair strategies. This comprehensive course is designed to provide you with an in-depth understanding of how these repairs fit into the […]

Calendar of Events

S Sun

M Mon

T Tue

W Wed

T Thu

F Fri

S Sat

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

Questions? Visit Our FAQ Page

Available ETI Training Courses

On-Demand Training

API 579 Fitness-for-Service – General Metal Loss (Part 4)

This on-demand training course provides a detailed overview of the methodology and application of assessment procedures for General Metal Loss (GML) found in Part 4 of API 579-1 / ASME FFS-1.

Mechanical Integrity Issues in HF Alkylation Units

This on-demand course introduces the most common mechanical integrity (MI) issues that affect the fixed equipment in HF Alky units and offers ways to mitigate those problems.

Introduction to Risk-Based Inspection

This on-demand course provides a general overview of Risk-Based Inspection focusing on the fundamental concepts and basic principles of mitigating risk through inspection.

Introduction to Alarm Management Systems

This on-demand course provides a comprehensive overview of alarm management systems in industrial environments, emphasizing the importance of effectively managing alarms to enhance safety, efficiency, and compliance.

Hybrid Instructor-Led Training

API RBI Software

You will learn how to use API RBI software and helps you understand API RP 581 technology, interpret its calculated results to help develop an effective RBI program.

Damage Mechanisms for Chemical and Petrochemical Industries

This course provides an overview of the primary damage mechanisms(DM) applicable to fixed equipment in the chemical and petrochemical industry and included in API RP 571.

Fundamentals of Asset Lifecycle Management (FALCM)

The course provides a practical understanding of the basics of piping design and analysis rules of the ASME Process Piping Code, B31.3 (ASME B31.3).

Intro to Instrumentation and Process Control

You will learn about the application, hardware, installation, and performance of process measurement instrumentation and control valves.

Intro to Materials Engineering

This course delivers a practical understanding of the plant materials used in the fabrication of process plant pressure vessels and piping systems, which are key to equipment reliability.

Intro to Welding Engineering

The course will introduce several common welding processes, discuss filler metal identification and selection, review key elements of welding procedures and qualifications, and provide guidance for field-applied heat treatments.

Intro to eec Webtools

The eec WebTools course is an introduction to the eec WebTools environment, and has options for advanced training for eecPlantEngineer, and IntelliJoint.

Mechanical Integrity Program

Learn how the MI program fits within an overall asset management program, compliments reliability efforts, and applies across the life cycle of assets – from the design, fabrication, and construction, through the installation, operation, and decommissioning phases.

Piping Vibration

This course provides an overview of piping vibration measurement and severity analysis, guidance on identification, evaluation, and mitigation of piping vibration problems.

Pressure Vessels: Design By Analysis I & II

DBA I provides background information related to the original development and evolution of DBA technology in ASME Section VIII Division 2 (VIII-2). DBA II builds upon the principles established in DBA I and offers an in-depth overview of the material properties needed to perform DBA. Additionally, a summary of the VIII-2 DBA methods for quantifying protection against plastic collapse, local failure, and buckling will be provided.

Pressure Vessels: Fatigue I & II

Fatigue I covers fundamentals of cyclic loading and metal fatigue, including common definitions, an overview of cyclic plasticity principles, and different types of fatigue damage morphology. Fatigue II reflects a continuation of Equity’s Fatigue I Course and includes content on the Battelle Structural Stress Method for welded fatigue applications and the use of the Strain-Life Equation to predict remaining life.

Pressure Vessels: ASME VIII-1

This course provides an overview of the pressure vessel design rules of the ASME Boler & Pressure Vessel Code, Section VIII, Division 1 (ASME VIII-1), including a review of the general requirements, component design, material consideration, fabrication, and examination and testing.

Pressure Vessels: ASME VIII-2

This course covers the nine parts of the ASME Boler & Pressure Vessel Code VIII-2, including general a review of the general requirements, responsibilities and duties, design by rule (DBR), design by analysis (DBA), and pressure vessel overpressure protection.

Process Piping

DBA I provides background information related to the original development and evolution of DBA technology in ASME Section VIII Division 2 (VIII-2). DBA II builds upon the principles established in DBA I and offers an in-depth overview of the material properties needed to perform DBA. Additionally, a summary of the VIII-2 DBA methods for quantifying protection against plastic collapse, local failure, and buckling will be provided.

SagePlusTM Software

SIMFLEX-IV Software

The course covers an overview of the SIMFLEX-IV program features, input structure, analysis procedures, input keywords, output description, and other special topics. Recommended prerequisite: basic understanding of ASME B31.3 Process Piping Code.

Storage Tanks

During this course, storage tank engineers will gain a practical understanding of the basics of tank design and analysis, including material considerations, fabrication, and examination.