Tips, Tricks, and Best Practices to Expedite and Maximize the Value of Fitness-for-Service Assessments

FFS technology is used to optimize run, repair, or replace decisions for equipment containing flaws or defects. API 579-1/ASME FFS-1 (API 579) is the international code that provides Level 1, Level 2, and Level 3 FFS procedures to assess various damage mechanisms. This presentation will provide the novice or intermediate experienced FFS practitioner an overview […]

Gulf Coast Lunch & Learn: What’s New in Piping Integrity Management

You’re invited to join us on June 17 for a comprehensive overview of the latest changes in API RP 574 related to structural minimum thickness requirements. Don’t miss your opportunity to hear about the changes from Kraig Shipley, who is technical support for the development of the new structural minimum thickness rules for API 574.

Ongoing Technology Developments in the Fitness-for-Service (API 579-1/ASME FFS-1) Joint Committee

Fitness-for-Service (FFS) technology has significantly evolved since the initial publication of API RP 579 in 2000. With each subsequent edition of the document, there have been significant upgrades to existing technology as well as the introduction of new technology that has proven to provide tremendous value to owner-operators by providing a safe and justifiable means […]

Pressure Vessels: ASME VIII-1

Gain a solid, practical understanding of pressure vessel design with this in-depth training course, focused on the requirements of the ASME Boiler & Pressure Vessel Code, Section VIII, Division 1 (ASME VIII-1). Learn the Code's organization and its key content, including its general requirements, component design, materials, fabrication, and testing procedures. Build competency in the […]

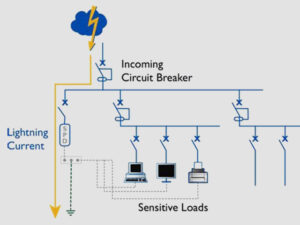

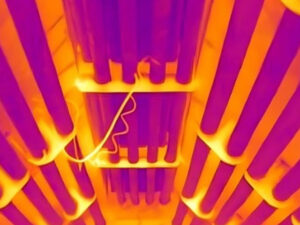

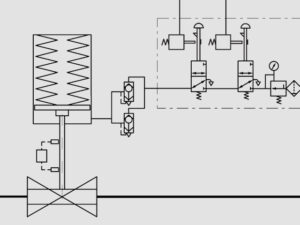

Designing Pressure Relief Systems for Heat Exchanger Tube Ruptures

When designing pressure relieving systems for heat exchangers, the potential for internal tube failure needs to be considered, particularly if there is a significant difference in design pressure between the shell-side and tube-side of the exchanger. As per API STD 521, Pressure Relieving and Depressuring Systems, if the operational pressure on one side exceeds the […]

Storage Tanks August 18 – 20 & 27 – 28, 2025

Learn the essential knowledge needed for effective welded storage tank design and analysis with this comprehensive course. Focused on the key requirements of API 650, this course equips attendees with a practical understanding of aboveground storage tank design and analysis. Through expert instruction, you’ll gain insights into critical aspects such as roof designs, foundations, material […]

Developments in Aboveground Storage Tank Engineering Solutions

Aboveground storage tank (AST) engineers must contend with an ever-evolving landscape of operational requirements, environmental loads, inspection technologies, and industry best practices to achieve reliability goals. These dynamic factors affect all phases of AST lifecycle management, and proper foresight is needed to beneficially leverage the coming changes. This presentation will use real-world case studies to […]

Storage Tanks August 18 – 20 & 27 – 28, 2025

Learn the essential knowledge needed for effective welded storage tank design and analysis with this comprehensive course. Focused on the key requirements of API 650, this course equips attendees with a practical understanding of aboveground storage tank design and analysis. Through expert instruction, you’ll gain insights into critical aspects such as roof designs, foundations, material […]

Process Piping

This engaging course offers a practical and comprehensive understanding of the piping design and analysis requirements outlined in the ASME B31.3 Process Piping Code. You’ll explore critical topics such as piping component and system design, material selection, fabrication, and inspection/testing. Key areas like design loads, internal pressure considerations, piping flexibility analysis, branch reinforcement calculations, temperature […]