ANSWERS TO TODAY'S INDUSTRY CHALLENGES

Aging infrastructure, growing knowledge gaps, fewer qualified employees, changing jurisdictional requirements, and a push to produce sustainable products or services. These issues are relevant to all processing facilities.

At Equity, we combine our industry expertise, codes and standards knowledge with a multi-disciplinary approach to address these common challenges. Our consulting services, corporate standards, and software help you improve facility-wide safety, increase inspection efficiencies, reduce equipment downtime, and maximize operational reliability.

- Home

- Industries

How We Help Your Industry

Eliminate Knowledge Gaps

The crew change is here, your subject matter experts (SMEs) are retiring, and there are fewer personnel available to fill those roles. The Equity Engineering Practices (EEPs) capture SME knowledge and integrate that information into the industry’s most comprehensive corporate standards. The EEPs are accessible to all employees, which increases the safety and reliability of your facility.

Comply with Jurisdictional Codes & Regulations

In every industry, jurisdictional requirements are changing to meet environmental targets and address sustainable operations. As active members on many API and ASME committees, we know the codes and standards and use this knowledge on every project and technology we deliver. We help you meet jurisdictional requirements without over-engineering.

Minimize Unplanned Maintenance or Shutdown

Unplanned maintenance or shutdowns are expensive. The equipment needs to restart quickly to minimize production and revenue losses. E2G offers pre-turnaround planning, proactive fitness-for-service (FFS) assessments, and risk-based inspection (RBI) program implementation to help you minimize unplanned shutdowns, improve equipment reliability, and reduce operational risk.

Industries We Work With

Oil & Gas

Address the evolving needs in the upstream and downstream energy industries with E2G’s extensive engineering experience and software.

Midstream

Maintain the safety and integrity of aboveground storage tanks, terminals, and pipelines with proactive engineering services.

Chemicals & Petrochemicals

Minimize hazards and improve operational safety processing polymers, petrochemicals, and other feedstocks.

Nitrogen & Fertilizers

Control inspection costs, minimize corrosion or HTHA concerns, and improve reliability to meet the growing global demand for fertilizers and potash.

Renewables & Alternative Energy

Join the energy transition by shifting to sustainable production and operations while balancing operational reliability.

Other Industries

Manage risk, control inspection costs, and create safe operating environments at all types of industrial processing facilities, including nuclear energy, pharmaceuticals, and aerospace.

Industry Insights

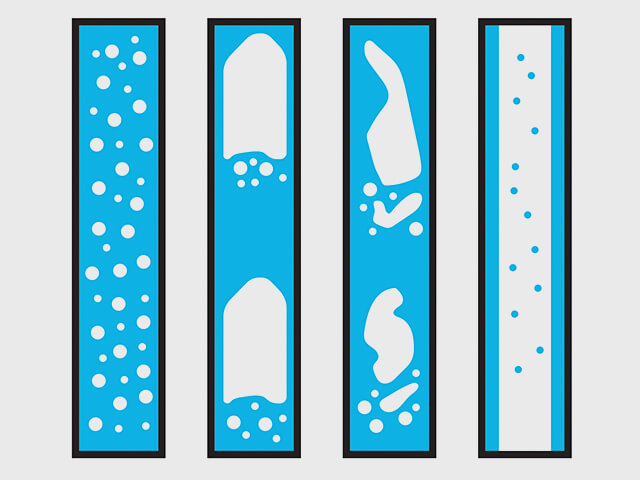

Two-Phase Flow Piping Vibration

Two-phase flow creates complex dynamic forces that can lead to catastrophic fatigue failure, yet traditional restraints often clash with high-temperature thermal expansion needs. This article explores how to diagnose flow regimes and use advanced metrics like kurtosis to design effective, thermally safe remediation strategies.

A Detailed Approach to Slug Flow and its Consequences

Two-phase flow is a common challenge in chemical process equipment that can lead to costly malfunctions, high pressure drops, and damaging mechanical vibrations. This article explores how to use mechanistic modeling and liquid holdup analysis to identify unstable flow regimes like slug flow before they cause fatigue failure or other risks to integrity. Learn how strategic piping configurations and dynamic hydraulic analysis can ensure process stability and protect your facility.

Testimonials

Our Experts

Equity is your “go-to” consultants for the hard-to-solve problems. Equity is internationally recognized in the refining, petrochemical, and chemical industries as a leader on aging infrastructure services and support. Our team combines their extensive experience with state-of-the-art technology to help extend the lifecycle of your existing assets and create safe operating environments.

Our experts:

- Are primary authors on WRC 528 and WRC 562

- Are lead investigators on API 579, API 571, and API 581

- Have been an API 520 task force chairperson for more than 25 years

- Are members of API sub-committee of mechanical equipment (SOME)

- Are certified ISO VCAT-IV vibration analysts