Equity Technical Institute (ETI) has a core objective to transfer knowledge. We take this objective to include a transfer of knowledge both internally and externally. Like many industries, the petrochemical, chemical, and related industries show an increase in aging workforce. The baby boomer generation currently makes up a larger portion of the professional workforce (including engineers and inspectors) than the rest of the entire professional workforce combined. There is a high cost of losing the intellectual capital and knowledge from this generation, making the transfer of knowledge even more critical in the coming years.

ETI has an internal program to hire and develop the next generation of subject matter experts (SMEs). We also have a curriculum designed to do the same for our clients. In this issue of Industry Insights, we will examine the curricula we have developed for clients and are internally using to develop our engineers and inspectors.

The MI Training Curriculum and Project SME

ETI has developed a detailed curriculum in our Equity Engineering Practices (EEPs) to serve as the necessary training component in a mechanical integrity (MI) program (as required by the PSM standard OSHA 1910.119) and that is also based in our lifecycle management philosophy. This training curriculum serves several purposes other than meeting regulatory requirements. It provides an overview of MI topics to most personnel at a facility to create awareness, develops the necessary expertise required by personnel in various technical areas, and serves to transfer knowledge from current to future SMEs.

The EEPs MI training curriculum consists of a dozen tracks, or areas, of MI-related training (and an EEP-related track for EEPs clients). Some of the tracks include Inspection & Testing (I&T), Pressure Vessels & Tanks (PVT), and Piping (PIP). In each track, there are generally three to six “courses.”

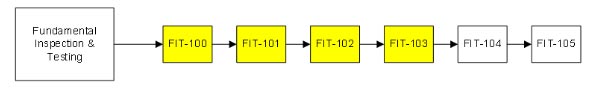

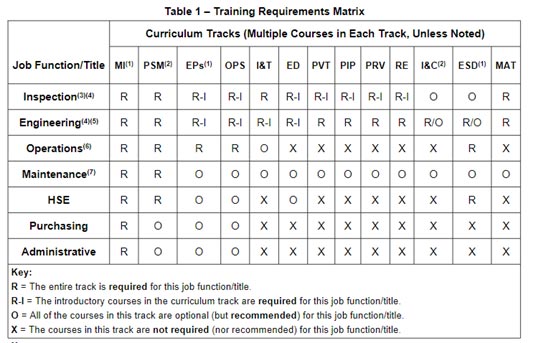

Some of these are fairly introductory and aimed at a more general audience, while some get deeper into the specific technology areas and are aimed at inspectors, engineers, specialists, etc. In the I&T track, the introductory-level courses (FIT-100 through FIT-103, highlighted in Figure 1) are basic courses on inspection standards such as API 510. The two additional courses are advanced I&T topics for inspectors and inspection specialists. In total, the MI training curriculum includes about 50 individual courses. In the EEPs, there is a training matrix (Figure 2) that further differentiates the expected training (required, optional, not required) for various facility personnel categories. All personnel can gain something from learning more about most or all aspects of a facility’s operation, and the degree to which administrative and other functions should be involved in MI-related training may be limited.

ETI has developed customized subsets of this curriculum for various clients. Additional courses may be developed and delivered related to other specific processes or specific to a hazardous chemical being stored or processed (e.g., for a course on specific MI requirements for ammonia storage). Of course, in some facilities, not all of the training courses in the matrix may apply. For example, a facility may not have pipelines, so for that case, pipeline-related I&T and PVT courses may be omitted.

As an integral part of the broader Equity organization, ETI has developed a subset of this curriculum for the Equity Engineering and CorrSolutions technical staff. We have named this internal curriculum “Project SME.” The formal, instructor-led training aspects of Project SME consist of a series of courses in various areas key to both our business and our clients, such as I&T, PVT, fitness-for-service (FFS), and risk-based inspection (RBI). It also consists of a weekly learning series where individuals train all technical staff on a focused, industry-relevant subject, and like the matrix in Figure 2 shows, we provide and encourage some level of training within all categories of personnel across Equity. While this instructor-led training is a part of Project SME, it is not the only means by which we are training the next generation. The remainder of Project SME is the mentorship and on-the-job training that occurs through project work, codes & standards (committee) work, and work on our EEPs. This knowledge transfer occurs organically given the knowledge transfer objective and culture that exists at Equity.

Many of the technical personnel in our industry are certified or licensed and have ongoing professional development requirements. These may include some number of continuing education or professional development credits each renewal period. In addition to professional license requirements, we encourage all our team members to pursue lifelong learning and professional development opportunities to further their career development. This is recognized in our MI training curriculum established in our EEPs and in our own Project SME. ETI’s senior personnel undergo refresher training and other professional development to maintain credentials, but also to keep current with best practices, codes, standards, and other issues affecting our industry.

Training Format and Delivery

Many of the courses in the MI curriculum are part of ETI’s API-U training offerings. ETI is an API-preferred provider of these technical training courses: Fitness-for-Service, Risk-Based Inspection, Pressure Relieving Systems, and Damage Mechanisms in the Refining, Chemical, and Petrochemical Industries. Other ETI technical training courses are part of our Equity Technical Institute (ETI) that offer training instruction regarding ASME Pressure Vessels, Piping Vibration, Storage Tanks, Materials & Corrosion, Welding and Fired Heaters, API RBI Software, SagePlus™ Software, etc. Most of the MI curriculum that ETI has developed has been taught in person, although it can be delivered through instructor-led virtual courses if in-person training is not practical due to travel restrictions or logistical/cost concerns. We emphasize live instructor-led training that facilitates instructor-student discussion and interaction. Most of our virtual training is provided in 4-hour increments to create a more effective learning experience, as we have found that learning and retention suffers during longer virtual sessions.

Whether the training is in-person or taught virtually, ETI’s training courses generally feature a team of two instructors. This format is rather unique to ETI, as other technical training providers typically use only one instructor. The benefits of two instructors are obvious:

- Different backgrounds and experiences are shared with the attendees

- Team-teaching results in efficiency and efficacy during the delivery of course content

- More “energy” is available to engage attendees due to a shared workload

- Any issues are resolved without interruption of instruction

For most of our publicly offered courses, we deliver training via a hybrid format, in person in our Shaker Heights, Ohio office and a virtual option to attend remotely.

To accommodate everyone’s busy schedules, ETI is committed to creating and producing on-demand video courses that can be completed online anytime, anywhere, and at one’s own pace. The same exceptional subject matter experts (SMEs) who lead our instructor-led courses share their extensive experience through these on-demand offerings. Topics range widely—from general metal loss fitness-for-service (FFS) assessment techniques covered in API 579 Part 4 to strategies for preventing equipment failures through proper mitigation of common damage mechanisms. In addition to our on-demand courses, our library of recorded webinars also offers flexible learning across a broad spectrum of topics, allowing individuals to learn according to their own schedules.

The Obligation of Professional Development

ETI has invested significant time and resources into training the next generation of SMEs. We treat knowledge transfer as an obligation to the industry and the young engineers and inspectors that we hire. It is through this training investment in our professional staff and our continued commitment to codes & standards committees (API, ASME, NACE, etc.) that we hope to contribute to a well-trained group of future SMEs. For more information on ETI’s training programs, please submit the form below: