The Equity Engineering Practices® (EEPs) are a customizable set of Best Practices that are currently being used by nearly 40 companies. The EEPs serve a big portion of the US refining industry, with over 36% of US refineries subscribing to the EEPs, but the EEPs have grown to be much more, serving hundreds of facilities in the energy, petrochemicals, chemicals, renewables, fertilizers, pharmaceuticals, food processing, and other specialty sectors. The EEPs help owner/users in each of these industries to manage their equipment and facilities from “cradle to grave” over the entire lifecycle of their equipment and infrastructure. E2G | The Equity Engineering Group, Inc. has recently taken the EEPs to another level by developing the Reuse Practices (RUPs) and further serving our end clients by providing the EEPs to Engineering, Procurement, and Construction (EP&C) companies. This article will focus on the use of the EEPs in capital projects, repurposing projects, and over the lifecycle of your assets.

The EEPS – A Historic Look

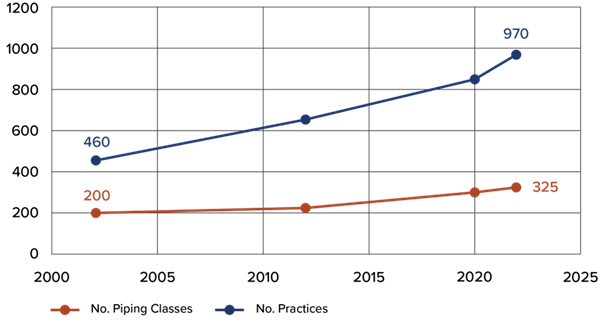

First, a look at the look at the evolution of the EEPs. The EEPs have been around for over 20 years. When E2G went into business in the early 2000s, one of the first products we provided were the Practices. Over the years, there has been phenomenal growth in the EEPs, not just in a ten-fold increase in the number of clients using the Practices, but in the EEPs collection itself. The early EEPs collection consisted of about 450 Practices in 15 main subject matter areas, and just under 200 piping classes. Today, the EEPs collection includes nearly 1000 Practices in 21 subject matter areas, and over 300 piping classes, and the collection is growing every year to fulfill client needs.

In recent years, E2G has added sections on Marine Facility Design and Maintenance, Solids Handling, Mechanical Integrity (MI) Programs, Special Emphasis MI Programs, Pipeline Facility Design, and Pipeline Facility Maintenance. We also added a new collection, the RUPs, which provides the procedures needed to evaluate existing equipment and infrastructure for reuse, or repurposing. This new collection is largely aimed at helping our clients with their evaluations of equipment and related infrastructure being repurposed to meet the need for production of renewable fuels and other renewables products. Finally, over the past few years, we’ve begun to “internationalize” our key Practices in a collection (IEPS) that helps our multi-national clients design and maintain equipment in many parts of the world.

During the time all this effort was being put into development and maintenance of the EEPs, E2G has put its software expertise to use in developing a new and improved delivery platform. The new 2.0 website provides clients many enhanced tools, and even better support on EEPs usage in everything from major capital projects to smaller upgrades and day-to-day inspection and maintenance activities.

CAD Integration

Available with the EEPs collection is a piping database of over 300 pre-engineered piping classes based on industry standards. One big challenge for capital project teams has historically been that each project requires piping classes to be recreated in 3D CAD modeling systems. Once these piping classes are recreated, teams are required to execute quality checks to ensure the CAD classes comply with all the original piping class requirements. This effort introduces a variety of inefficiencies – adding time, cost, and potential errors to each project. To address this issue, E²G has developed and provides a CAD Conversion Tool. The CAD Conversion Tool allows E²G to export the customized client piping databases as a project file that can be imported directly into CAD software. There are many benefits for organizations that utilize this tool, including:

Time and Money Savings

- Initial savings – The entire piping database is converted into a CAD-compatible format at a significantly reduced cost and timeframe vs. manual effort.

- Short-term savings – The CAD file can be frozen along with current Best Practices and piping classes to support a project, thus eliminating the cost of an EP&C firm creating the files.

- Long-term savings – An updated CAD file can be provided as the piping classes evolve to align with changing Best Practices, reducing ongoing maintenance efforts

Quality Assurance

- Automation reduces human error in re-creating classes.

- Direct conversion ensures alignment between requirements in the piping database and CAD classes.

- Currently, the CAD Conversion Tool is compatible with Integraph’s CADWorx® program, and E²G is nearing completion of a tool that is compatible with AutoCAD®’s Plant 3D software. The CAD Conversion Tool is being provided to existing EEPs clients as an add-on to their current subscription.

Projects

To prevent requirements from changing throughout a capital project or a repurposing effort, most organizations typically freeze a copy of the EEPs to lock in specific requirements that are to be used for the entirety of that project. To support this effort, in the early days, E²G would provide a copy of the collection on a DVD or upload the locked collection to a ShareFile location. The challenge with this form of delivery is that users of the locked collections lose the powerful, enhanced website tools such as Searches and Material Take-Off (MTO) generation. To improve record retention and allow capital project teams to take full advantage of the 2.0 website, E²G has developed and enhanced a tool called Projects. Projects allows organizations to create locked copies of the customized collections directly through the website, basically freezing a copy of the website. To access the locked collection, users simply select the project from within the website, and, upon selection, the only viewable content on the website will consist of the version of the Practices and piping classes as they were at the time the project was locked.

To improve ease of use for individuals working on a specific project, Projects allows each organization to limit contractor access so that the contractor can directly access the locked collection, but not the live content all within a single web link. An authorized project manager can lock and even update content within Projects themselves on the website, including Best Practices and legacy content that the organization has uploaded to the website for their users. Once complete, Projects will stay available to the organization on the website as needed. Projects is currently being offered as a standard service for all EEPs users and has been used to support numerous capital projects.

Legacy Content

Another feature that the 2.0 website has introduced is Collection where organizations can upload and maintain content. There is often content within an organization that may not fall into the category of Best Engineering Practice or Standard but is closely related. For example, an organization might have local laws or regulations that are relevant to the management of equipment or facilities, and these documents can be maintained in Collection.

Documents in Collection can be linked with EEPs using associations. The association to EEPs will be seen on the list of documents, making it clear to users that an EEP has an associated legacy document and vice versa. Documents in a Collection can be locked to Projects just as EEPs and piping classes. There is no limit to the number of Collections an organization creates.

Reuse Practices

As clients look to repurpose assets to production of renewable energy and renewable products, E2G has drawn on its experience in suitability-for-service (SFS) assessments and reuse assessments to develop a new collection within the EEPs on “reuse.” The RUPs cover the requirements for the evaluation of equipment (fixed and rotating), piping, storage tanks, instrumentation and controls, and structures in new services. Materials review, operations review, inspection and maintenance history reviews, and financial evaluation of replacement versus modification are all covered in the RUPs. Worksheets and other checklists that improve the repurposing evaluation process are included in the collection. Like the base EEP collection, the RUPs draw on hundreds of years of subject matter expert (SME) experience, much of this going back to E2G SMEs’ early experience in repurposing refinery units. The RUPs integrate into the based collection or can stand alone for companies wishing to evaluate only reuse. The same strong management systems and 2.0 website tools that come with the EEP collection can be used with the RUP collection.

The E2G Difference

The EEPs are a tried-and-true product developed by E2G SMEs with hundreds of years of industry experience coupled with thousands of “client SME years” of best practices and lessons learned to improve safety and reliability at EEPs client facilities. This emphasis on safety and reliability over the entire facility lifecycle ultimately saves our clients time and money when considering reducing future problems, lowering future inspection and maintenance costs, and providing greater equipment availability.

The EEPs and their growth, however, didn’t come without a lot of hard work. Over the 20-plus years, E2G has committed over 75,000 hours of its engineers in the development of the EEPs. Additionally, we have spent more than 200,000 hours of our engineers in the maintenance of the EEP collection over the same 20-plus years. More than 60% of E2G’s FULL-TIME Consulting Engineering staff is dedicated to the development and maintenance of the EEPs. Each and every year, we reaffirm, on average, 180 Practices. Each and every year, we develop, on average, more than 35 new Practices, and we develop or customize dozens of new piping classes. In addition, our Practices group has nearly 2 dozen document specialists, software specialists, and support staff whose only job is to help maintain and improve the EEPs product, customized and delivered to each client on the state-of-the-art 2.0 website. This is not a passing fancy for E2G.

For more information on our EEPs, please contact Susie Szymanski by submitting the form below: