It is no secret that many of the subject matter experts (SMEs) in the process industries are retiring. For many large, multi-national oil and gas companies, this isn’t necessarily an issue since many of these companies have well-developed, internal training programs for their new engineers. In fact, E2G teaches portions of these training programs. But many mid- to smaller-size companies often have limited SME resources and, thus, do not have a technical training program for recently hired engineers. The Fundamentals of Asset Lifecycle Management (FALCM) course is designed to help those companies train their new engineers. Let E2G’s SMEs train your future SMEs!

Many organizations hire engineers as plant, fixed equipment, reliability, and maintenance engineers, but these new engineering graduates leave college with no knowledge or formal training in these capacities. Engineering graduates do not finish school with an understanding of asset reliability, pressure vessel design, or piping flexibility considerations. If they are fortunate, they will find an SME to mentor them during the beginning of their career to quickly close the knowledge gaps and achieve basic competency. At E2G, we offer training courses that can accelerate that climb up the learning curve, beginning with our FALCM training course.

Since its founding, E2G | The Equity Engineering Group, Inc. has been committed to sharing knowledge within the oil and gas and petrochemical industries, and since 2006, E2G has been hosting technical training courses all over the world to share the technical expertise demonstrated by our experienced engineers. Furthermore, like you, E2G hires new engineers – which, although not common in the consulting industry, we think is worth doing. In the complementary Industry Insights article, you’ll read how we train our new engineers using a similar curriculum, the same course materials, and the same SMEs as instructors. To that end, E2G offers the FALCM course so our customers may begin to develop their own technical competency among the next generation of engineers.

To effectively develop your new engineers and demonstrate the best learning outcomes, it is important for the instructor to know what content to teach and how to teach it. One of the single best predictors of successful learning outcomes is the group of instructors teaching your new engineer. To teach FALCM, E2G will utilize some of our most highly accomplished SMEs who are also our most highly rated instructors. Many of these SMEs have been delivering exceptional technical instruction to thousands of new engineers throughout the world since 2006.

Course Description

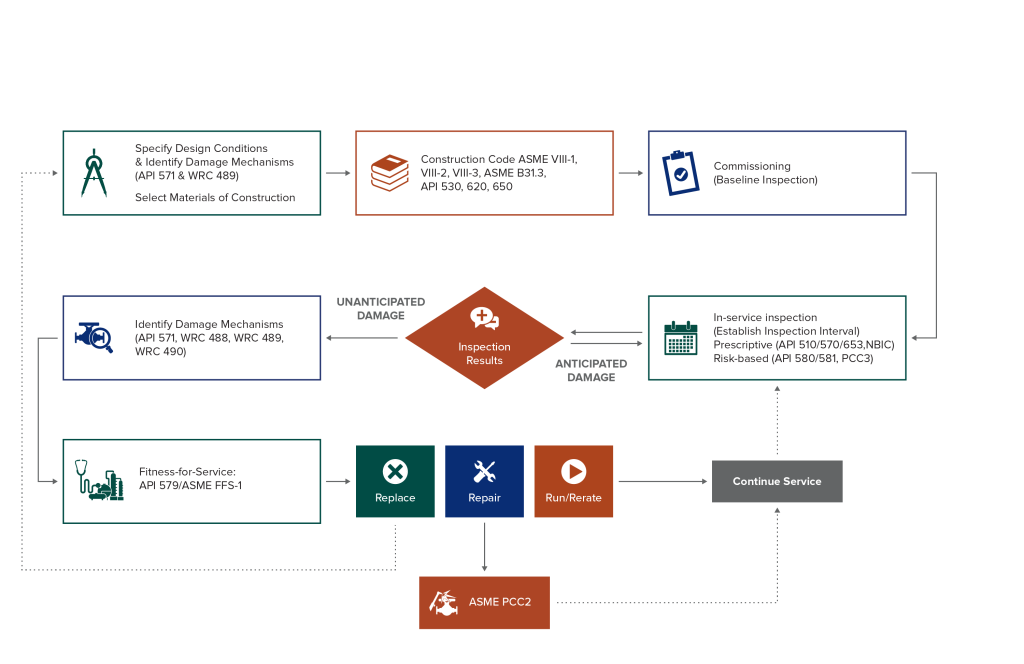

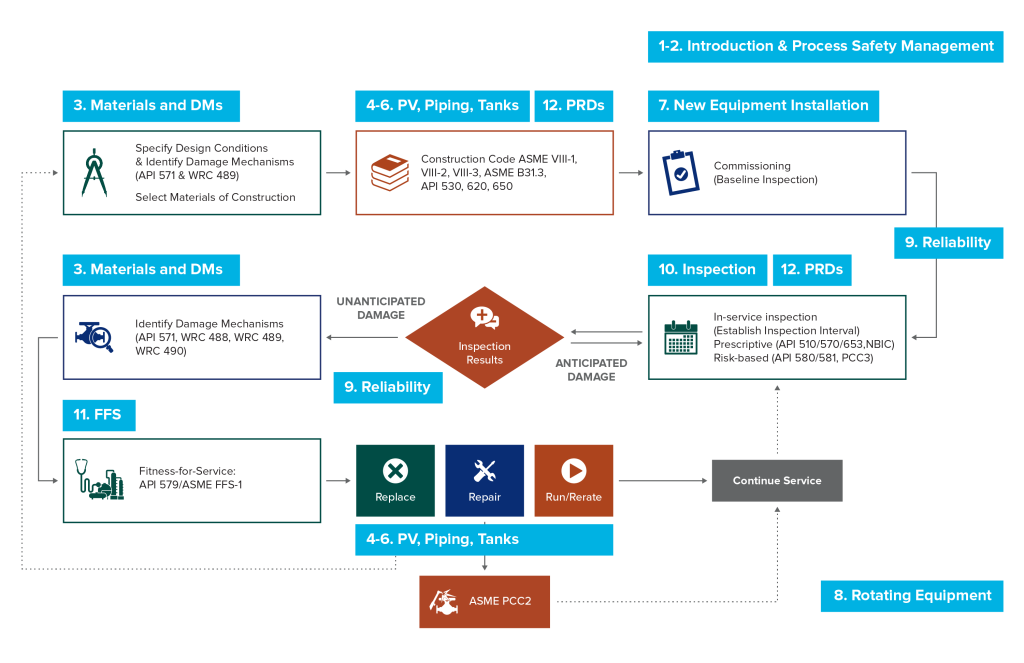

The FALCM course begins with describing the process of lifecycle management (LCM) of fixed equipment (Figure 1) and the importance of technical knowledge of owner/users to maximize safety and mechanical integrity (MI). Building on these ideas, the course turns to the basics of process safety management (PSM) and why this program is critical to the effective management of operational hazards. Next, the course shifts to fixed equipment conception and design, which begins with an understanding of common damage mechanisms and ways to eliminate or mitigate those threats via material selection. This sets the foundation for fixed equipment design using ASME and other construction codes.

The course also introduces new engineers to many of the basic equipment types found throughout oil and gas processing facilities: pressure vessels, piping, rotating equipment, and storage tanks. Once equipment design and function are known, the course trains the engineer in the basics of reliability, an often overlooked element of an engineer’s education, which emphasizes the goal of maximizing an asset’s performance throughout its lifecycle.

Closely related to reliability, inspection of in-service equipment and why it is an essential component of LCM are discussed. Techniques from API 579-1/ASME FFS-1 for assessing the equipment to determine if it is fit for continued service are presented for cases in which inspection finds damage to the equipment. Course attendees are then given an overview of one of the most important safety items found in these processing facilities: pressure relief devices. Finally, combining many facets of what they have learned, engineers learn best practices to design, purchase, procure, install, and commission equipment that meets MI and PSM requirements.

This course is intended for recently hired engineers in the oil and gas, petrochemical, chemical, fertilizer, pulp and paper, power generation, and related process industries. It is suitable for engineers who work in plant engineering, reliability, maintenance, project management, or MI roles for midstream or downstream business operations.

Though it is designed with the new engineer in mind, personnel working in inspection, operations, and turnaround planning would likely benefit from learning the fundamentals of asset LCM.

FALCM Topics & Instructors

The FALCM course topics are taught by E2G’s most qualified SMEs.

- Introduction and LCM

- Process Safety Management (PSM) – James Olson

- Materials & Damage Mechanisms (DMs) – Kenneth K. Kirkham, P.E. and Nathaniel G. Sutton, P.E.

- Pressure Vessels – James C. Sowinski, P.E.

- Piping – Kraig S. Shipley, P.E.

- Storage Tanks – Joel L. Andreani, P.E.

- New Equipment Installation – James Olson

- Rotating Equipment – Michael F.P. Bifano, Ph.D., P.E.

- Reliability – James Olson

- Inspection – Jim McVay

- Fitness-for-Service (FFS) – Brian R. Macejko, P.E.

- Pressure Relief Devices (PRDs) – Philip A. Henry, P.E.

Duration & Schedule

This course will be delivered over five days within one work week, eight hours per day, for a total of 40 hours of instruction.

Course delivery is a hybrid format, allowing the attendees to choose one of the following options:

- In-person attendance at E2G’s headquarters in Shaker Heights, Ohio

- Virtual attendance using MS Teams or a similar conferencing application

As described above, the FALCM course serves as an introduction to the fundamentals of managing assets throughout their lifecycles. Once the new engineer has completed the FALCM course, more in-depth training is available in many other E2G training courses, including API-U or Equity Technology Institute (ETI).

If you would like to discuss customizing the FALCM course for your organization or have any additional questions for E2G’s Training Lead, Mark Harmody, please submit the form below.