The Applied Research & Development (ARD) Team at E2G recently kicked off a number of projects geared towards bringing explainable Artificial Intelligence (AI) to the energy industry. These projects will develop solutions to help clients manage the integrity of their aging assets using artificially intelligent tools as part of the decision-making process. Over the past few years, the ARD Team has been developing a novel infrastructure called BENGI (Bayesian ENGine for Insights). BENGI is a high-performing computational AI engine for solving probabilistic Bayesian Decision Networks specifically for industrial applications (e.g., inspection optimization, predictive maintenance, anomaly detection, smart diagnostics, etc.). To solve the large-scale nature of these problems, the ARD Team is incorporating improved solution algorithms that use high-performance computing paradigms to push the envelope of what has been done previously with these methods.

This large-scale effort is partially funded by the Department of Energy (DOE), and we are actively working on projects that integrate BENGI into integrity management software platforms for the nuclear and pipeline transportation industries. The first project, called CAN2, ensures the long-term performance of welded stainless-steel spent nuclear fuel dry storage canisters that are subject to chloride-induced stress corrosion cracking. Incorporating this platform into daily operations promotes proactive decision-making and improved risk management to minimize the likelihood of a potentially catastrophic failure event (i.e., loss of the canister’s containment boundary).

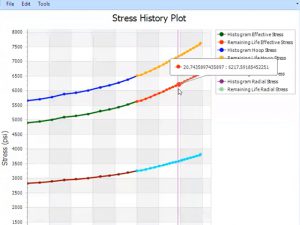

The second project, called PipeSight, leverages an integrated CPU/GPU high-performance computing environment to interrogate in-line inspection scans for threats, determine the best corrosion rate by spatially correlating scans taken at different times, and automatically perform Level 1, 2, and 3 engineering critical assessments of threats to ultimately optimize inspection planning.

As a precursor to and beneficiary of these two projects, we are integrating Bayesian stochastic methods into a cloud thickness management software platform for predicting circuit corrosion rates, detecting local corrosion, justifying condition monitoring location (CML) quantity/placement, and improving thickness management programs. This product, known as ThinSight, will be available for beta users later this year. Expect to see continued updates on these exciting opportunities as we bring these advanced technologies, and numerous others, to many of our software products over the coming years.