At a Glance:

This article explores High-Integrity Pressure Protection Systems (HIPPSs) as a proactive safety instrumented system (SIS) in upstream oil and gas and pipeline transport to prevent overpressure events by isolating the source, offering an instrumented alternative to traditional pressure relief valves and flare systems. It details HIPPS fundamentals, adherence to international standards like IEC 61508 and IEC 61511 for Safety Integrity Level (SIL), and contrasts HIPPSs with conventional relief systems highlighting benefits like reduced environmental impact and lower infrastructure costs. The article also discusses design considerations, different types of HIPPSs (mechanical vs. electronic with DCS, ESD, F&G system integration, and redundancy), and future trends including IIoT and digital twin technology for enhanced predictive maintenance and cybersecurity.

High-pressure conditions in upstream oil and gas production as well as pipeline transport pose significant safety and environmental risks. Traditional mechanical solutions like pressure relief valves and flare systems have limitations due to venting constraints, regulations, and spatial issues. High-Integrity Pressure Protection Systems (HIPPSs) offer a proactive alternative by isolating the source of overpressure instead of venting it. This article discusses the application, benefits, challenges, and future of HIPPSs in these environments.

HIPPS Fundamentals

An HIPPS is an independent safety instrumented system (SIS) designed to prevent overpressure by shutting off the source of pressure. The functional loop consists of three primary elements:

- Sensors: Either electronic or mechanical initiators that detect abnormal pressure conditions

- Logic Solver: Electronic HIPPS used to process input signals and initiate shutdown logic

- Final Elements: Typically fast-acting valves that isolate the pressure source

The system is designed to achieve a specific Safety Integrity Level (SIL), as defined by IEC 61508 and IEC 61511 standards. By preventing pressure escalation beyond design limits, HIPPSs can eliminate the need for large flare systems and reduce associated emissions.

Standards and Compliance

HIPPS design and implementation are governed by multiple international standards:

- ASME Boiler and Pressure Vessel Code, Section VIII, Divisions 1 and 2 (previously Code Case 2211): Permit HIPPSs as an alternative to relief devices under specific conditions. The user must justify the use of an HIPPS with a risk analysis and documentation demonstrating the system is sufficiently reliable to meet the company’s risk tolerance.

- API Recommended Practice 521: Recommends HIPPSs only when the use of a pressure relief device is impractical, such as in cases of high flow rates or environmental concerns related to flaring. The user must justify impracticality and ensure compliance with local regulations.

- IEC 61508 & IEC 61511: These international standards govern the design, implementation, and management of SISs, including HIPPSs. They define requirements for functional safety, safety lifecycle management, and the assignment of SILs based on risk analysis. IEC 61511 specifically addresses the process industry sector.

- ANSI/ISA 84.01: This standard (now largely harmonized with IEC 61511) provides guidance on the application of SISs, including HIPPSs, in the process industries. It outlines requirements for system design, validation, and ongoing performance monitoring.

- ISO 10418:2019: This standard provides guidance for offshore surfaces application of HIPPSs. Per IEC 61511, offshore use will require SIL assignment. This standard is not for subsea HIPPS design and implementation.

Adherence to these standards ensures HIPPSs are rigorously tested, verified, and maintained throughout their operational life. Through comprehensive risk analysis and proper documentation, an HIPPS must demonstrate that it can independently and reliably detect unsafe high-pressure conditions and provide a level of safety at least equal to a traditional relief system.

HIPPSs vs. Conventional Relief Systems

Traditional overpressure protection involves mechanical relief valves that vent to flare systems. These systems can be space-consuming, environmentally taxing, and difficult to scale for high-flow scenarios.

HIPPSs are preferable when:

- Environmental or regulatory reasons require emissions to be minimized

- Size, cost, or complexity result in an impractical conventional relief system

- High SIL (i.e., high integrity and reliability) is required

- An upgrade of the existing flare systems would be prohibitively expensive

Conventional Relief Systems are preferable when:

- Priorities of design include simplicity, reliability, and ease of maintenance

- The application is well-understood and does not justify the complexity or cost of HIPPSs

- Immediate venting or flaring is acceptable or required by process design

HIPPS provides:

- Faster Response Times: Total response time of an HIPPS includes the time required to detect an overpressure condition, process the signal, and fully close a shutdown valve, and it must be fast enough to prevent downstream pressure from exceeding safe limits. This time is shorter than the process safety time (PST) available to remain within its design pressure.

- Reduced Environmental Impact: Prevents release of hydrocarbons and minimizes flaring.

- Lower Infrastructure Costs: Eliminates the need for oversized relief and flare systems.

Although HIPPSs provide faster response time than the PST with lower environmental impact and infrastructure cost, they do require rigorous validation and higher initial engineering efforts to ensure reliability and compliance.

Pipeline and Upstream Use Cases

A search on HIPPS case studies reveals the following common themes: cost savings, environmental benefits, technical feasibility, safety and compliance, and application diversity.

Case Study 1: Remote Gas Production Manifold – A remote onshore gas production facility utilized HIPPS to protect a pipeline rated below the maximum wellhead pressure. The HIPPS enabled the operator to use a lower-class pipeline without compromising safety, resulting in significant CapEx savings.

Case Study 2: Offshore High-Pressure Export Line – An offshore platform employed HIPPS to protect a high-pressure export pipeline. The HIPPS eliminated the need for large flare capacity, reduced topside weight, and complied with zero-flaring policies.

These cases demonstrate HIPPS as both a safety and economic enabler in complex installations.

Design and Engineering Considerations

Effective HIPPS design requires:

- Overpressure Scenario Analysis: Identify credible events and required mitigation. Conduct a formal hazard analysis, such as a Hazard and Operability Study (HAZOP) with Layer of Protection Analysis (LOPA), Fault Tree, or “What-If” Analysis, to identify all credible overpressure scenarios. The results from the hazard analysis will be used to determine the required SIL, which will quantify the level of risk reduction needed.

- Redundancy: Typically employs voting logic for pressure transmitters or switches (e.g., 2oo3) to ensure accurate and reliable detection of overpressure events.

- Validation and Testing: Must facilitate periodic proof testing and functional testing during the functional acceptance test (FAT) and site acceptance test (SAT) to maintain the required SIL over the system’s lifecycle. FAT and SAT are two key stages in verifying industrial equipment or system performance meets contractual and design specifications.

Attention must be paid to the selection of the components of each subsystem and the integration of diagnostics for fault detection to minimize spurious trips and maximize reliability.

Two Types of HIPPSs

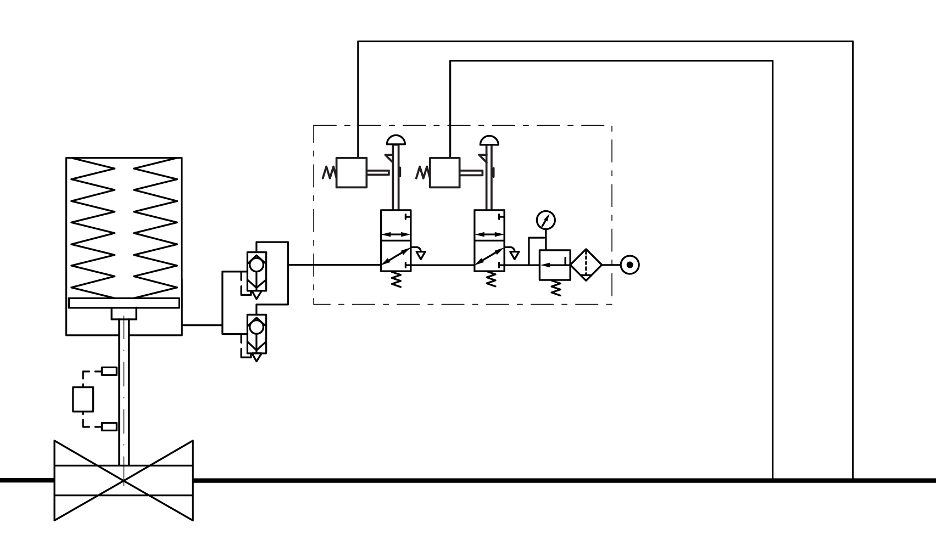

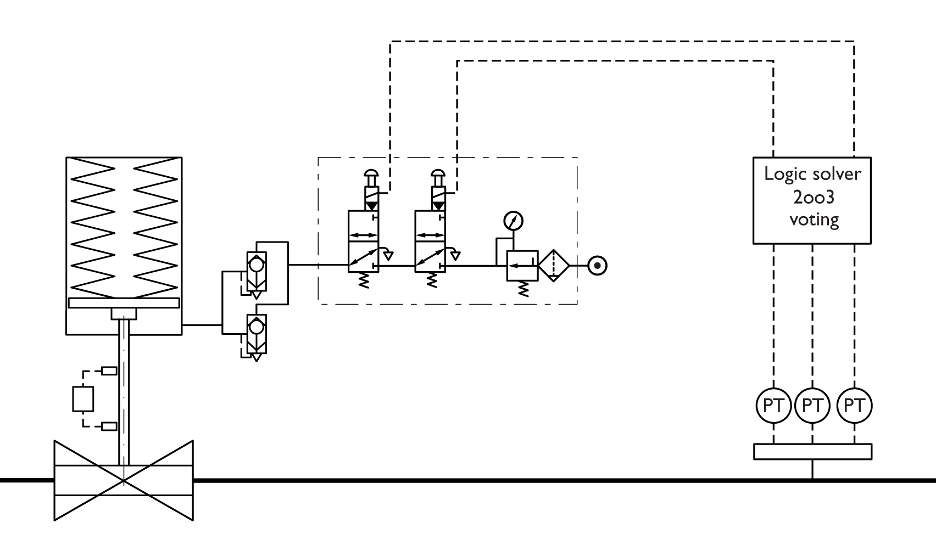

Mechanical HIPPSs operate through direct pressure sensing using spring-loaded mechanisms, pilot-operated valves, or rupture disc systems (Figure 1). When process pressure exceeds the predetermined setpoint, the mechanical force directly actuates the protective action without requiring electrical signals, logic solvers, or external energy sources. Electronic HIPPSs employ electronic pressure transmitters or switches, a programmable logic system, and fast-acting valves with actuators and solenoids (Figure 2).

Mechanical HIPPSs

Mechanical HIPPSs do not rely on electrical power but still accomplish the overpressure protection requirements of high-pressure isolation with use of mechanical initiators.

Key characteristics:

- No Electric Power Required: Without the requirement of an external electrical source, this system is ideal for remote or hazardous locations where power supply may be unreliable or unavailable. The mechanical initiators are pressure switches or sensors that can directly detect the overpressure and trigger the shutdown mechanism.

- Fast Closure: With typical isolation valve closure being less than two seconds, this system is engineered for rapid isolation of high-pressure sources.

- Types of Actuation:

- Self-actuated pneumatic: Uses instrument air or gas supply if available.

- Self-contained hydraulic: Utilizes a local oil tank and manual pump for actuation.

- Low Pressure Drop: During normal operation, this system is designed so that there is minimal pressure drop across the isolation valve when open.

- Bi-directional Flow and Piggable Lines: Suitable for applications requiring flow in both directions and for pipelines that need to be pigged (cleaned or inspected internally).

Electronic HIPPS – Integration with Control and Safety Systems

Electronic HIPPSs must interface seamlessly with Distributed Control Systems (DCSs), Emergency Shutdown Systems (ESDs), and Fire & Gas Systems. Some key characteristics of electronic HIPPS design include:

- Communication Protocols: Use of standard industrial protocols (e.g., HART, Modbus, Profibus) will allow functional separation to preserve the HIPPS as an independent safety function. This integration allows for advanced diagnostics, remote status monitoring, and system health checks.

- Cybersecurity: Protection against unauthorized access and tampering.

- Voting Logic and Fault Tolerance: Triple modular redundant (TMR) architecture with 2oo3 voting is typically employed, requiring at least two of the three channels to agree before taking action, thus preventing spurious trips.

- Flexible Installation: Because there are no limits on the distance between sensors and final elements, electronic HIPPSs are suitable for large or complex facilities where the source of pressure might be quite a distance away. There is even capability to employ a remote solar power system to power a logic solver to control an HIPPS in gas wellhead applications.

Effective integration improves overall plant safety and supports coordinated responses to abnormal conditions.

Compared to mechanical systems, electronic HIPPSs offer several advantages, such as quicker response times, enhanced diagnostic capabilities, and seamless integration with modern plant control systems, all while meeting the stringent reliability standards required for safety-critical applications.

Challenges and Lessons Learned

While HIPPSs can offer substantial benefits when a conventional relief system is impractical, implementation challenges include:

- Spurious Trips: False activations due to sensor drift or signal noise. Incorrect component selection can reduce system performance or cause nuisance trips.

- Maintenance Requirements: Maintenance is required to ensure reliability in extreme temperatures, humidity, or corrosive atmospheres. The maintenance program should include availability of spare parts for critical components.

- Testing Requirements: HIPPSs demand rigorous testing including partial stroke testing of the valves and complete functional testing to maintain their SIL rating. Conducting these tests often requires process interruption and skilled personnel.

- Vendor Management and Selection: Careful evaluation is needed to ensure appropriate technology platforms and vendors are selected based on long-term support, obsolescence management, and cybersecurity considerations. This selection ensures compatibility and performance across multiple hardware and software components.

Addressing these issues requires robust design reviews, thorough testing, and detailed maintenance procedures. Operating personnel require comprehensive training to ensure the maintenance of the HIPPS does not lead to operation issues due to lack of understanding of the complex system behaviors and limitations.

Future Trends

The overall trajectory shows HIPPS technology evolving from traditional mechanical safety systems to intelligent, connected platforms that provide enhanced safety while offering better operational insights and maintenance efficiency. The evolution of HIPPS technology is influenced by digitalization and sustainability goals.

- Digital Integration and Smart Systems: HIPPSs are increasingly incorporating digital technologies such as Industrial Internet of Things (IIoT) sensors. This use of digital technology allows for advanced analytics for real-time monitoring and predictive maintenance capabilities, thus allowing for better system diagnostics and reduced downtime.

- Industry Expansion: While traditionally dominant in oil and gas applications, HIPPS technology is expanding into other sectors including petrochemicals, power generation, and renewable energy infrastructure, as these industries recognize the importance of overpressure protection. The push for zero-flaring and methane leak reduction increases HIPPS adoption across these other sectors.

- Integration with Digital Twin Technology: Future HIPPS implementations are likely to incorporate digital twin modeling for better system simulation, testing, and optimization before deployment. This will enable real-time performance modeling and predictive maintenance.

- Cybersecurity Enhancement: As HIPPS become more connected and digitized, cybersecurity features are becoming increasingly important to protect critical safety infrastructure from potential cyber threats.

- Modular and Flexible Designs: Existing trend toward more modular HIPPS configurations that can be easily adapted to different process requirements and scaled as needed.

- Condition-Based Monitoring: Advanced diagnostic capabilities and condition monitoring are being integrated to provide continuous assessment of system health and performance.

These advancements position HIPPSs as a core component of modern, intelligent safety systems.

Conclusion

HIPPSs provide a robust, sustainable, and cost-effective solution in upstream and pipeline operations. In some applications, HIPPSs may be the only solution when conventional overpressure protection methods are impractical. When designed correctly, aligned with industry standards, and integrated with other safety mechanisms, HIPPSs can greatly improve operational safety and lower emissions. With advancements in digital technology, HIPPSs are expected to become smarter, more predictive, and increasingly vital to safety management strategies within the energy industry.

Please contact the author with any questions by submitting the form below: