Biofuels & Renewable Fuels Processing

Balance Reliability with Profitability

The biofuels market is estimated to be worth $307 Billion USD by 2030. As part of the energy transition, companies are changing existing facilities to process renewable fuels, and governments are supporting this transition by offering credits to renewable fuel producers.

The profitability of a renewable diesel unit or other fuel-from-biomass project lies in the speed in which the company can bring products to market. You need the right balance of reliability in design and materials with profitability and speed to market and take advantage of existing tax credits and renewable identification number (RIN) prices.

At Equity, our engineering team has experience with asset lifecycle management (LCM) for several types of renewable fuels and biodiesel units, including those processing:

- Soybean oil

- Distiller’s corn oil (DCO)

- Animal fats (tallow)

- Used cooking oil (UCO)

- Co-product oils from other biomass sources

Equity also provides renewable fuels producers with cost-effective solutions for raw and pre-treated renewable feed storage and pre-treatment units.

Reduce project time & costs

Improve safety

Maintain reliability

Evaluate your Assets for Repurpose or Reuse

Profitability is linked to understanding if you can reuse or repurpose existing equipment to process renewable fuels. We help you identify the most cost and time-effective changes to existing equipment to allow reliable biofuels processing and will provide practical inspection strategies after the equipment is repurposed.

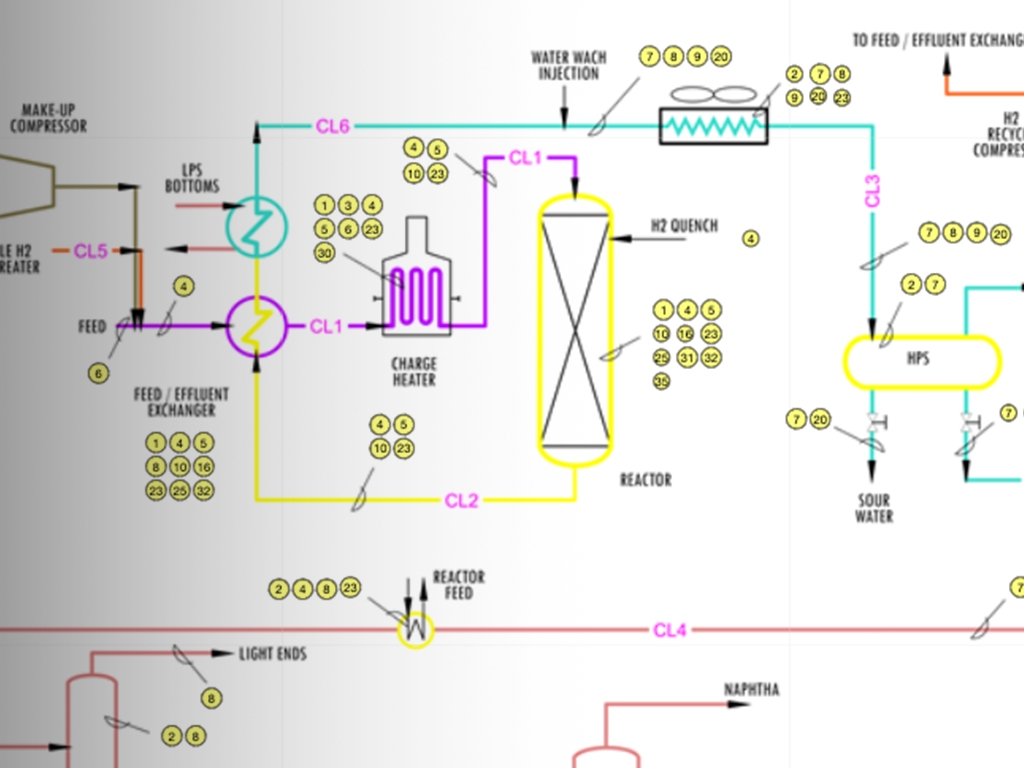

- Damage mechanism reviews and material selection or modification – select practical construction methods and identify new damage mechanisms or changes in severity for existing mechanisms due to the introduction of renewable feeds.

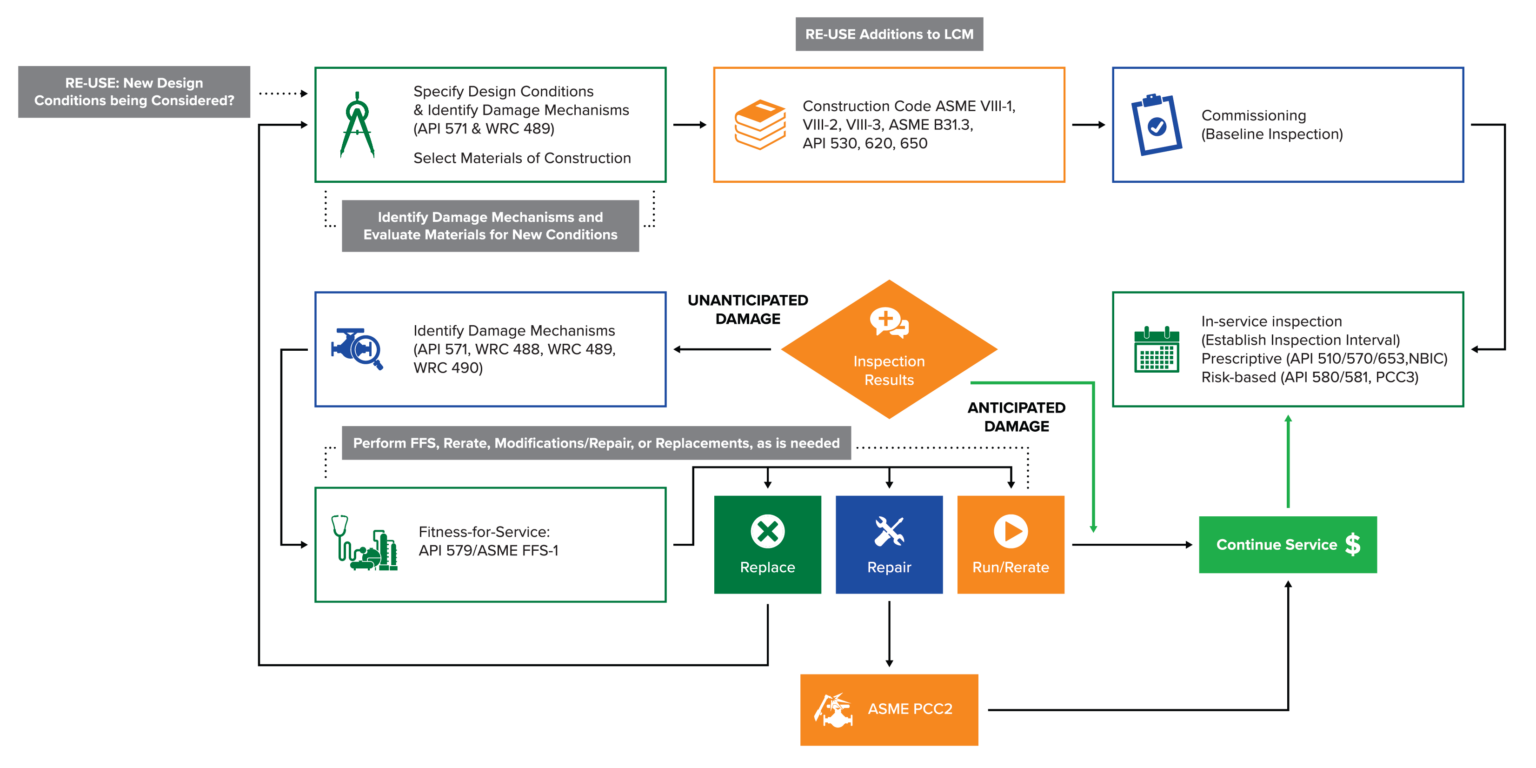

- Asset & Mechanical Integrity (MI) – align your MI program with the reuse goals to understand the impact that repurposing existing equipment will have on the asset’s LCM.

- Equity Engineering Practices (EEPs) Re-Use Practices (RUPs) – the RUPs are focused on re-use evaluations for equipment, piping, structures, and other infrastructure.

- Fitness-for-Service (FFS) & Suitability-for-Service (SFS) – repurposing evaluations share many of the same multi-disciplinary features as a large FFS or SFS project. We understand the collaboration required for a successful re-use evaluation.

The major damage mechanisms that affect sections of renewables processing and biodiesel units are very similar to petroleum refining. At Equity, we consider feedstock source changes and identify the effect on damage mechanism susceptibility. During a Damage Mechanism Review (DMR), we work with you to identify active and potential damage mechanisms and use that data to calculate the impacts on corrosion.

Materials Selection & Process Alteration Recommendations

Knowing which materials or process to select will save time and money when repurposing a facility to renewable fuels or biodiesel. Equity collaborates with your capital project group to maintain project costs and schedules, identify alternative chemical treatments, and ensures the equipment is robust against the applicable damage mechanisms. Our construction material specifications balance reliability with your need to get the fuels to market quickly.

Incorporate IOWs into the project to provide flexibility in time and cost for equipment processing renewable fuels or biodiesel. Corrosion control documents (CCDs) and IOWs are instrumental to mechanical integrity and RBI programs as they outline the proper design, construction, operation, monitoring, inspection, and mechanical integrity improvements for your facility or equipment. We also consider the effects on downstream equipment when recommending limits on key process and corrosion variables.

The Equity Engineering Practices (EEPs) Re-Use collection supports owner-users evaluating how to repurpose or reuse equipment for new conditions, renewable fuels, and biodiesel. The RUPs incorporate the requirements for the evaluation of equipment (fixed and rotating), piping, storage tanks, instrumentation and controls, and structures in new services. The RUPs also include materials review, operations review, inspection and maintenance history reviews, and financial evaluation of replacement versus modification.

Recommended Reading

- Biofuels & Renewables /

- Equity Engineering Practices (EEPs) /

- Library /

- Re-Use & Re-Purpose /

- Biofuels & Renewables /

- Damage Mechanisms /

- Library /

- Materials & Corrosion /

- Webinars /

- Damage Mechanisms /

- Industry Insights /

- Library /

- Materials & Corrosion /

- Biofuels & Renewables /

- Equity Engineering Practices (EEPs) /

- Industry Insights /

- Library /

- Mechanical & Structural Engineering /

- Re-Use & Re-Purpose /

Renewable Fuels Expertise

With any new process technology, uncertainty regarding corrosion mechanisms and lack of data or direct experience can lead to over-conservative decisions that prolong a project and increase its costs. We leverage our expertise in renewable fuels with our extensive knowledge of traditional refineries, petrochemical, chemical process, ethanol production industries to provide the optimal solutions. We’re focused on creating safe operating environments and controlling risk.