- Home

- Engineering

- Materials & Corrosion

- CCD & IOW

CCDs & IOWs

What’s your process for monitoring equipment limits?

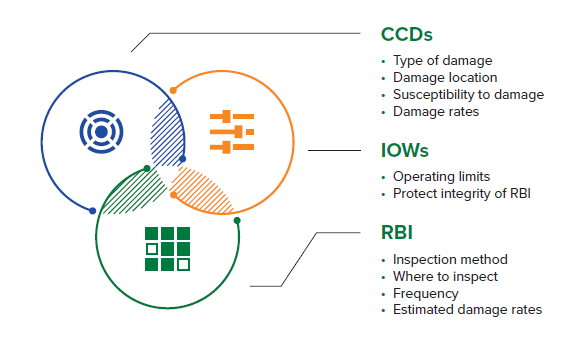

Corrosion control documents (CCDs) and integrity operating windows (IOWs) manage fixed equipment damage mechanisms and establish optimum operating ranges for specific equipment. Refineries, petrochemical, chemical, and other industrial processing facilities all benefit from implementing IOWs and CCDs to prevent failures, optimize production, and extend an asset’s life span.

API RP 970 provides recommendations on developing, applying, and maintaining CCDs; however, the recommendations generally remain at the owner’s discretion. Up-to-date documentation improves inspection effectiveness and turnaround planning and, most importantly, minimizes the risk of process leaks and unplanned shutdowns. Equity will help you develop site-specific IOWs and CCDs using API 970 and API 584 as guidelines.

Why do you need IOWs and CCDs?

Proactive tools that:

- Manage damage rates, create operating limits, and establish monitoring programs

- Support turnaround planning and shutdown/start-up strategies

- Provide recommendations for equipment upgrades, replacements, and process changes

CCDs and IOWs are reliability tools that help move a plant organization from reactive to proactive.

IOWs

IOWs provide actionable steps to all employees if and when equipment exceeds the recommended limits.

- Establish limits for process equipment to maintain integrity and improve reliability

- Promote predictable damage rates

- Minimize risk of process leaks and unplanned shutdowns

CCDs

CCDs summarize a process unit’s most likely damage mechanisms by breaking the unit into corrosion systems or loops.

- IOWs are (or should be) a subset and an integral part of an effective CCD

- CCDs should be developed as a precursor to a risk-based inspection (RBI) program

- CCDs should cover all fixed equipment in a process unit, not only vessels

Recommended Reading

- CCDs & IOWs /

- Library /

- Materials & Corrosion /

CCDs & IOWs Expertise

Equity follows a streamlined process to define IOWs and CCDs at an industrial manufacturing facility. We develop thorough CCDs and customized limits for each process unit by analyzing your equipment’s specific operation, stream chemistry, and metallurgy to minimize the likelihood of damage.

Our experts:

- Have 350+ years of combined field experience

- Pioneered development of FFS and RBI

- Are the primary authors on WRC 528 and WRC 562

- Serve as lead investigators on API 579 and API 571

- Provide emergency onsite support within 24 hours