INDUSTRY INSIGHTS NEWSLETTER

Welcome to Equity's Industry Insights Newsletter

Maintaining the mechanical integrity of piping systems is a constant challenge for process facilities, specifically where the interaction between high temperatures and complex fluid dynamics may lead to vibration-induced fatigue and thermal stress. This month Industry Insights includes articles that discuss how two-phase flow and slug flow can put piping systems at risk and offer advanced strategies for diagnosing and mitigating these complex problems.

Sign Up to Receive Industry Insights Sent to Your Inbox

Featured Articles

Two-Phase Flow Piping Vibration

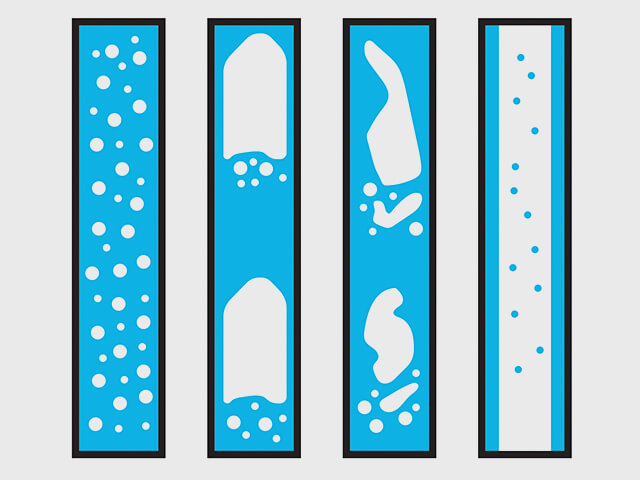

Two-phase flow creates complex dynamic forces that can lead to catastrophic fatigue failure, yet traditional restraints often clash with high-temperature thermal expansion needs. This article explores how to diagnose flow regimes and use advanced metrics like kurtosis to design effective, thermally safe remediation strategies.

A Detailed Approach to Slug Flow and its Consequences

Two-phase flow is a common challenge in chemical process equipment that can lead to costly malfunctions, high pressure drops, and damaging mechanical vibrations. This article explores how to use mechanistic modeling and liquid holdup analysis to identify unstable flow regimes like slug flow before they cause fatigue failure or other risks to integrity. Learn how strategic piping configurations and dynamic hydraulic analysis can ensure process stability and protect your facility.

Introduction to Piping Systems: Design & Integrity

Discover the fundamentals of piping system design and integrity in this introductory article for early-career engineers. Learn why piping matters, how reliable systems are built, and common pitfalls to avoid. Whether you’re new to the field or need a practical refresher, this article is a valuable starting point to learn about safe and effective piping systems.

Recently Published in the Industry Insights Newsletter

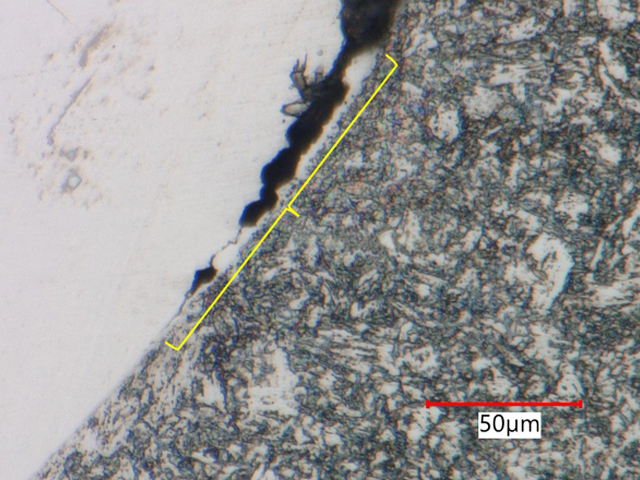

Dissimilar Metal Weld Repairs: Best Practices and Case Study

Dissimilar metal welds (DMWs) are often specified in process plants as an alternative to bolted mechanical joints and are successfully used in many corrosive and severe services. However, these welds can be subject to major weldability challenges and may lead to failures due to inherent material differences. In this article, the author examines these failure mechanisms, offers best practices for weld repairs and joint designs, and discusses a recent case study where laboratory analysis was used to identify the cause of a repeat DMW failure.

Bolted Flange Joint Assembly and Integrity

Learn how to improve performance by adopting inspection and maintenance best practices and applying advanced finite element analysis (FEA). This article discusses key design and operational considerations, drawing from codes and standards as well as Equity Engineering’s experience in assessing bolted joints.

Pipeline Defect Assessments for CSA Z662 Pipelines

Pipeline regulations in Canada differ from the ASME B31.4 and B31.8 standards used across the United States. In this article, the authors provide a detailed overview of the federally regulated CSA Z662 standard and clarify the differences between assessments (Section 10), engineering assessments (Section 3.4), and engineering critical assessments (Annex J & K). This is a must- read for any pipeline operators who wants to understand Canadian pipeline industry regulation and engineering assessment requirements.