NFPA 70E, Standard for Electrical Safety in the Workplace, has been a standard since its first publication in 1979 and covers the requirements for safe work practices to protect personnel by reducing exposure to major electrical hazards. This standard assists in complying with OSHA 1910 Subpart S and OSHA 1926 Subpart K. These standards have evolved over time to minimize hazards in the workplace.

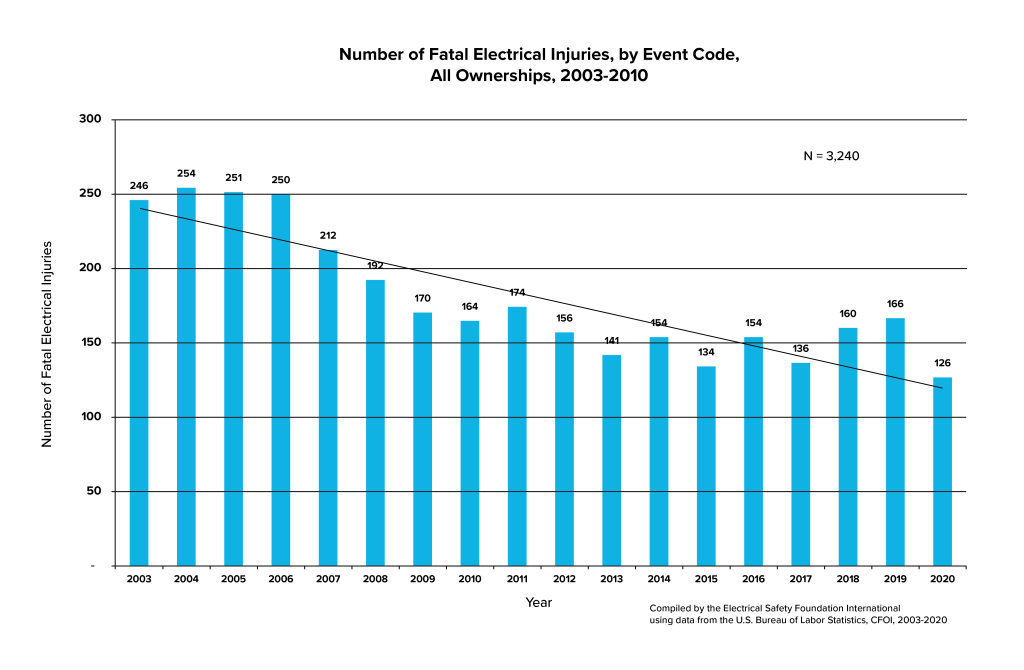

Using the U.S. Bureau of Labor Statistics (BLS) Census of Fatal Occupational Injuries (CFOI) and Survey of Occupational Injuries and Illnesses (SOII), each year the Electrical Safety Foundation International (ESFI) collects and publishes information on fatal and nonfatal occupational electrical injuries to their website: www.esfi.org. In general, injuries are trending down with 64%, the highest percentage of worker fatalities, occurring during tasks categorized as “Constructing, Repairing, Cleaning.”

NFPA 70E, 110.2(1) states that the electrically safe work condition policy “requires hazard elimination to be the first priority in the implementation of safety-related work practices.” There are six hierarchical elements of a risk assessment procedure, according to NFPA 70E, 110.3(H)(3). The assessment should be performed in this order of preference.

Elimination, substitution, and engineering controls are the most effective methods to reduce risk as they are usually applied at the source of possible injury or damage to health, and they are less likely to be affected by human error. Awareness, administrative controls, and personal protective equipment (PPE) are the least effective methods to reduce risk as they are not applied at the source, and they are more likely to be affected by human error.

- The primary and most effective means to establish an electrically safe working condition is elimination of the hazard. This is a state in which conductors have been disconnected from energized parts, locked/tagged in accordance with established standards, tested to verify the absence of voltage and, if necessary, temporarily grounded.

- Working on the control circuit in lieu of the line voltage would reduce the risk of an incident.

- NFPA 70, Article 240.87 was introduced in the 2017 edition of the National Electrical Code and is an example of using Engineering Controls to mitigate risk. Arc energy reduction switches are now required on overcurrent protection devices rated 1200 amps or higher.

- The labels found on most electrical panels are a great example of signage and labeling that alert the worker to the potential hazard.

- The requirement of a Hot Work Permit would be an example of the Administrative Control part of the pyramid.

- While still a critical piece of protecting worker from harm, note that PPE is the least effective way to avoid an incident.

In this article, we’ll focus on the primary and most effective means to create an electrically safe work condition: elimination of the hazard.

Any time qualified personnel intend to work on electrical equipment equal to or above 50V and within the limited approach boundary, the conductors and parts must be put into an electrically safe work condition before starting to work. NFPA 70E, Table 130.4(E)(a) defines the limited approach boundary distances and is based on the voltage and shock hazard that exists. In most industrial facility instances, the work is completed on 480VAC. The approach boundary in this case is 3 feet, 6 inches.

There are exceptions to this requirement, and they include:

- Shutting off the power will introduce additional hazards or increased risk of injury.

- The task is not feasible while de-energized due to operational or design limitations. If a voltage measurement must be taken, the equipment must be powered.

Many times, the inconvenience of powering down is used as justification for requiring or requesting a worker to complete the work while powered. It’s critical to remember that the potential human error in this situation creates an unnecessary hazard and can cause an unscheduled outage, requiring repairs to equipment.

These steps should be followed to eliminate the hazard:

- Determine all possible sources of power and check appropriate drawings, diagrams, tags, and similar signage. While it is tedious to update one-line drawings after minor changes, it is imperative to have updated drawings for worker safety. When a load has both normal power and generator backup and/or a UPS, all these sources of power must be disconnected as the first step.

- Interrupt the load, then open the disconnecting means for the equipment. For example, when powering down an air conditioning unit, it is safer to shut it off at the thermostat before disconnecting the breaker at the panel or compressor itself.

- If possible, visually verify that the disconnecting means is open. If visually verifying would require putting the worker in an unsafe condition, it is not required.

- Release any stored electrical energy. Capacitors or batteries that store electrical energy after power is removed must be discharged or disconnected from the load in question.

- Block or relieve stored nonelectrical energy in devices to prevent energizing electrical conductors or equipment. Breakers that have closing springs, for example, would need to have the tension on mechanical springs off.

- Apply lockout/tagout devices in accordance with established and documented procedures.

- Verify absence of voltage by testing the circuit or equipment for both line-to-line and line-to-neutral/ground voltage with a properly rated tester. Follow a “live dead live” procedure before taking each measurement to ensure the tester is operating properly.

- Ground circuit conductors if needed due to the possibility of induced or stored energy. This is not a common occurrence. If the area is close to a high-voltage transformer, it could possibly induce voltage on the equipment attempting to be placed in an electrically safe work condition. In a situation such as this, the conductors should be ground.

- Ground circuit conductors if they could contact energized conductors or parts. This is also not a common occurrence, but the step must be considered.

At the end of the day, safety is something everybody needs to be actively involved in. Every worker wants to go home at the end of their day and avoid any injury that would detrimentally change their quality of life.

This procedure is one part of the Electrical Safety Program every employer is required to implement. NFPA 70 (NEC), NFPA 70B Standard for Electrical Equipment Maintenance, and NFPA 70E Standard for Electrical Safety in the Workplace outline documentation, training, and audit requirements. For more information regarding electrical safety and reliability audits, contact the author below.