INDUSTRY INSIGHTS NEWSLETTER

Welcome to Equity's Industry Insights Newsletter

This month’s Industry Insights explores process safety from two critical angles: how advanced gas dispersion modeling can deliver more accurate, defensible consequence analysis; and an Engineering 101 article that offers foundational information about the process safety lifecycle. These articles are a good reminder that the best-performing facilities treat process safety as an engineering discipline that demands continuous investment in both people and technology.

Sign Up to Receive Industry Insights Sent to Your Inbox

Featured Articles

Evolution of Gas Dispersion Modeling

As hazardous release scenarios grow more complex, outdated Gaussian plume models are leaving facilities either over-exposed to risk or over-invested in unnecessary safety infrastructure. This article explores how advanced gas dispersion modeling with rigorous thermodynamic calculations and 3D consequence contours delivers right-sized process safety decisions.

Asset Lifecycle Management: An Introduction to Process Safety

The most serious incidents in industrial history were not the result of a single equipment failure — they were the product of systemic breakdowns in design, operations, and management. Understanding how process safety works, and where it can fail, is essential knowledge for any engineer working with complex systems or hazardous materials.

Recently Published in the Industry Insights Newsletter

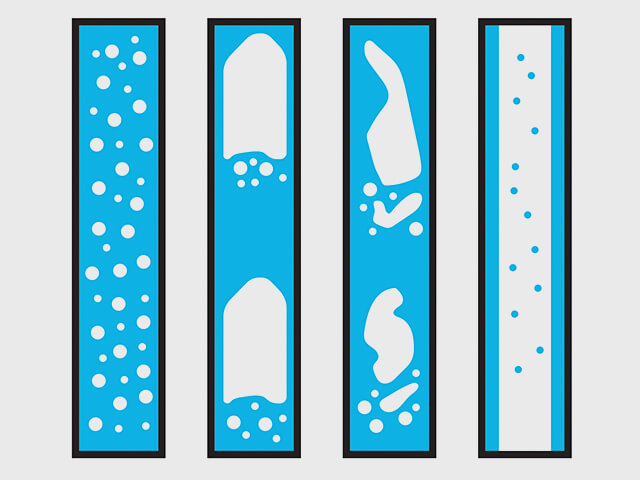

Two-Phase Flow Piping Vibration

Two-phase flow creates complex dynamic forces that can lead to catastrophic fatigue failure, yet traditional restraints often clash with high-temperature thermal expansion needs. This article explores how to diagnose flow regimes and use advanced metrics like kurtosis to design effective, thermally safe remediation strategies.

A Detailed Approach to Slug Flow and its Consequences

Two-phase flow is a common challenge in chemical process equipment that can lead to costly malfunctions, high pressure drops, and damaging mechanical vibrations. This article explores how to use mechanistic modeling and liquid holdup analysis to identify unstable flow regimes like slug flow before they cause fatigue failure or other risks to integrity. Learn how strategic piping configurations and dynamic hydraulic analysis can ensure process stability and protect your facility.

Introduction to Piping Systems: Design & Integrity

Discover the fundamentals of piping system design and integrity in this introductory article for early-career engineers. Learn why piping matters, how reliable systems are built, and common pitfalls to avoid. Whether you’re new to the field or need a practical refresher, this article is a valuable starting point to learn about safe and effective piping systems.