- Home

- Engineering

- Mechanical Integrity

- Asset Inspection Planning

ASSET INSPECTION PLANNING

Discover Your Full Operational Potential

Does your asset inspection plan account for new equipment or technology, corrosion or damage mechanisms, or comply with the latest codes and standards? Having a clearly defined asset inspection plan can increase the performance of your equipment, improve overall production, and maximize profitability. Equity conducted a two-week asset inspection plan review at a petrochemical facility, and by assessing the process conditions and operating capabilities, Equity provided practical recommendations that optimized operations and resulted in $40 million annual revenue. Increase your profitability with our turnkey facility inspection plan development and long-term inspection program management.

Maintain asset reliability

Prevent and mitigate major incidents

Optimize maintenance & inspection schedules

Minimize unplanned maintenance & shutdowns

Types of Inspection Planning Support

| New Facilities of Equipment | Large-Scale Facilities in Full Operation | Audits & Assessments | Project Design & Development |

|---|---|---|---|

|

|

|

|

Asset Inspection Planning Workflow

Our mechanical integrity team applies a multi-disciplinary approach to all asset inspection plans. We will assess your needs and develop a total solution that includes practical recommendations to improve safety, optimize production, and increase profitability. Our asset inspection planning workflow includes:

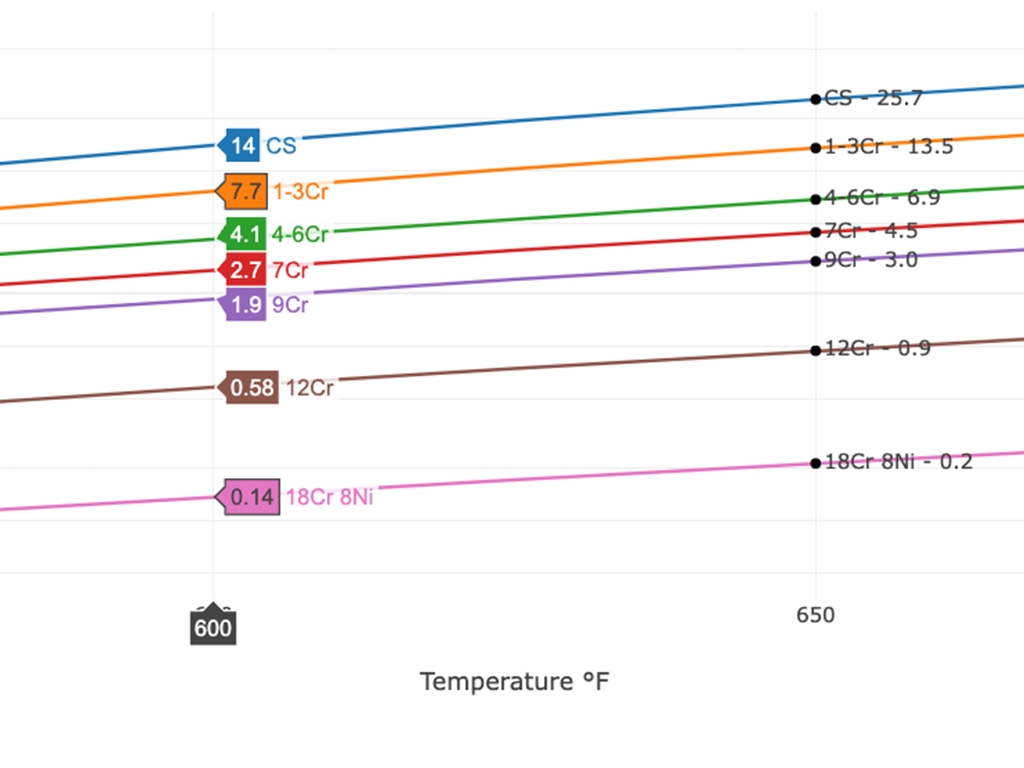

- Review damage mechanisms

- Update inspection testing method to reflect changes in technology and industry knowledge

- Create detailed inspection test plans (ITPs)

- Develop inspection program standards & procedures

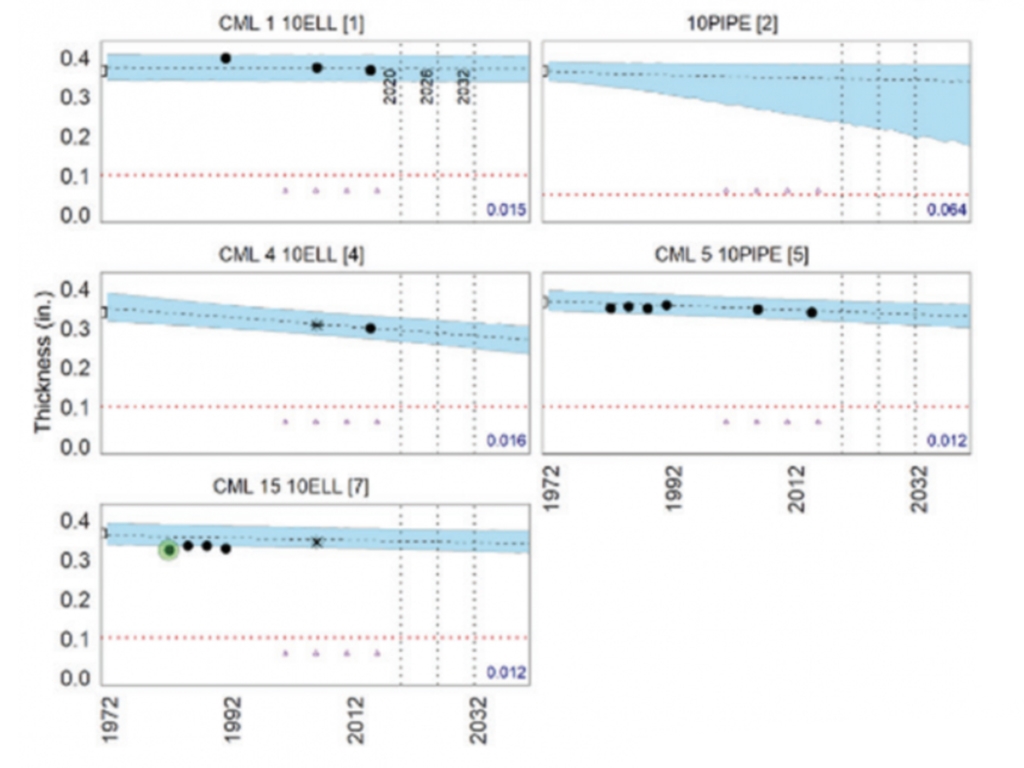

- Optimize corrosion monitoring locations (CMLs)

- Develop and execute special emphasis programs

Inspection Program Standards & Procedures

A successful asset inspection plan includes detailed inspection program standards and procedures that are accessible to the entire organization. Upload custom documentation and inspection program standards into the Equity Engineering Practices (EEPs), the industry’s most comprehensive corporate standards, to help personnel make informed design and maintenance decisions, minimize deviations, and promote safety and reliability.

Conducting proactive turnaround (TAR) planning helps you deliver a TAR on time and on budget, plus improve equipment reliability and reduce operational risks. Equity offers in-person or virtual TAR support to help you make fast, informed decisions before or during the scheduled shutdown.

Identify corrosion monitoring locations (CMLs) using advanced thickness analysis to find localized corrosion or thinning trends in your piping circuits. The CorrSolutions team analyzes your CML data to identify trends, develop mitigation strategies, and address any known data anomalies.

Recommended Reading

- Asset Management /

- Library /

- Mechanical Integrity /

- Webinars /

- Fitness-for-Service (FFS) /

- Industry Insights /

- Library /

- Mechanical & Structural Engineering /

- Risk-Based Inspection (RBI) /

- Turnarounds /

- Damage Mechanisms /

- Equity Engineering Practices (EEPs) /

- Industry Insights /

- Library /

- Mechanical Integrity /

- CCDs & IOWs /

- Industry Insights /

- Library /

- CorrSolutions /

- Library /

Asset & Mechanical Integrity Expertise

Continuous improvement is a key element of an MI program to ensure it evolves with changes in technology and requirements in the industry. E2G’s mechanical integrity team combines its industry experience with a multi-disciplinary approach to support your MI program improvements and the full lifecycle management of assets.

Our experts:

- Have 70+ years of combined field experience in petrochemical, chemical, and oil and gas industries

- Pioneered development of fitness-for-service (FFS) and risk-based inspection (RBI)

- Are primary authors on WRC 528 and WRC 562

- Are lead investigators on API 579, API 571, and API 581