At a Glance:

This article offers practical guidance for engineers managing refinery shutdowns and turnarounds (TARs), focusing on maximizing equipment integrity, process safety, and future reliability. It outlines key strategies for pre-TAR planning, including equipment history review, fitness-for-service (FFS) assessments (API 579), and critical path scrutiny to minimize unplanned downtime. The article also provides TAR execution guidance on on-site repair capabilities, forming a Problem-Solving Team (PST), and understanding post-weld heat treatment (PWHT), as well as post-TAR procedures like documenting FFS reports and updating risk-based inspection (RBI) plans.

Introduction

Refinery shutdowns and turnarounds (TARs) compress months of maintenance and inspection into a few intense weeks. As an engineer involved in TAR planning, execution, and completion, your decisions during this window directly affect equipment integrity, process safety, and future reliability. Depending on your experience and familiarity with the units, this can be a daunting task . The intent of this article is to provide practical guidance and tips to help make your TAR more successful.

Pre-TAR Guidance

Thorough planning before feed leaves the unit and shutdown activities begin is essential for efficient and safe work progression. Key recommendations include:

- Review Equipment History: Examine past inspections and corrosion data to identify high-risk equipment and prioritize assets needing special attention. This helps anticipate unplanned findings such as unexpected corrosion or cracking.

- Establish a Fitness-for-Service (FFS) Strategy: Develop a clear plan for applying FFS principles in accordance with API 579. Decide with refinery leadership whether FFS will be the first, second, or third response to unanticipated findings. This guides financial and scope decisions, such as prioritizing repairs that don’t affect the critical path or using FFS when the schedule is threatened.

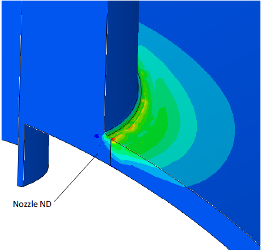

- Understand Inspection Limitations: If FFS is intended to avoid or minimize repairs during the TAR window, understand the capabilities and limitations of online inspection techniques. For example, localized corrosion near a nozzle junction with a reinforcement pad may not be monitorable from the vessel exterior during operation, making it a poor candidate for FFS.

- Critical Path Scrutiny: Apply additional engineering scrutiny to critical path items, including weld distortion assessments, to reduce the risk of delays from bulging or distortion due to weld metal buildup (WMBU). Coordinate with automated ultrasonic thickness (AUT) contractors and welding teams to limit weld deposition to necessary areas.

- Written Agreements on Cycle Times: Secure written agreements with management on TAR cycle times, including considerations like swoop-downs or catalyst changeouts. This provides flexibility for addressing discovery work without extending the schedule. Knowing the required cycle time for equipment is critical to support FFS assessments that defer repairs or replacements.

- Alignment on PWHT Requirements: Coordinate with the Materials & Corrosion group to clarify post-weld heat treatment (PWHT) requirements and weld repair expectations.

Proactive FFS Prior to TAR

Proactive FFS assessments can significantly streamline TAR execution, especially for equipment with complex damage mechanisms (e.g., creep, fatigue, cracking). Completing FFS work in advance allows for rapid decision-making during the TAR. For context, the lost opportunity cost for a TAR outage is estimated at $2.5 million/day for an average US refinery, so minimizing TAR duration is critical.

Examples of Proactive FFS

CUI Volumetric Damage: PAPI 579 Part 4 General Metal Loss (GML) and Part 5 Local Thin Area (LTA) assessments were performed for an amine tower with known corrosion under insulation (CUI) regions. Required thicknesses for various regions were provided, enabling quick decisions on weld repair during the TAR.

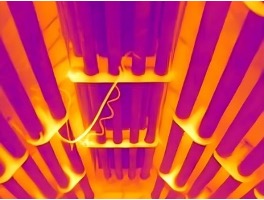

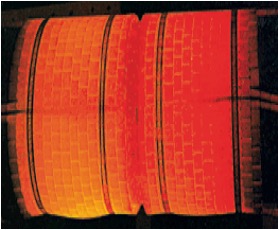

Heater Tube Remaining Life: API 579 Part 10 Creep assessments were conducted for six heaters planned for smart pigging. Preliminary reports were prepared for each heater, allowing rapid updates and decisions on tube replacements during the TAR.

CCR Reactor Repair Plan: Detailed non-linear creep finite element analysis (FEA) of a stacked CCR reactor quantified creep damage and identified high-damage regions for inspection. Critical flaw sizes and acceptable LTA grind-out areas were developed to guide repairs. Weld procedure specifications (WPSs) and PWHT guidance were provided along with structural assessments.

PWHT Plan: A complete PWHT plan for a scheduled weld repair was developed using WRC 452 guidance. Structural assessments confirmed the tower’s stability during 1200°F (648°C) PWHT, and requirements for freeing up ladders, platforms, and piping were documented. Piping and nozzle stress analyses determined whether piping needed to be disconnected.

Other proactive FFS assessments may include minimum allowable temperature (MAT) for hydrotests, minimum thickness calculations, flange bolting procedures, hydrogen bakeout assessments, weld repair plans, critical lift reviews, foundation checks, and more. Contact Equity Engineering for your specific needs using the contact form at the end of this article.

TAR Execution Guidance

With the extensive planning for a complex TAR complete, it is now time to focus on effective execution. The following recommendations will help ensure a successful TAR:

- Understand On-Site Repair Capabilities: Be aware of available specialty welding procedures and field machining options to minimize the need to send equipment off-site for repairs. Keeping components within the refinery fence line helps prevent mismanagement during cleaning, inspection, and repair processes.

- Assemble a Formal Problem-Solving Team (PST): Establish a dedicated team to address complex issues that may arise during discovery. For recommendations and team structure, refer to the Industry Insights Article: “Turnarounds – Executing a Problem-Solving Team.”

- Familiarize Yourself with PWHT Layout and Execution: Prepare for unexpected PWHT needs by understanding proper layout design and execution. WRC 452 outlines recommended practices for localized PWHT that are commonly followed by contractors. Ensure a detailed engineering evaluation is performed to confirm the structural stability of components during heat treatment.

- Document FFS Assessments: Create and maintain formal reports for any FFS assessments, including inspection data, photographs, assessment methodologies, results, and recommendations. This documentation is crucial for planning future equipment repairs or replacements.

- Conduct Field Reviews of Discovered Issues: Personally inspect any issues identified during the discovery process. What appears straightforward in inspection reports may be more complex in the field.

- Maintain Close Communication with the Inspection Team: Engage daily with the Inspection team to ensure all necessary information for FFS work is collected during initial inspections, reducing the need for follow-up inspections.

- Avoid Rushed Decisions: Do not feel pressured to provide immediate answers. Take the necessary time to gather all relevant facts and develop well-informed, optimized solutions.

Post-TAR Guidance

After completing a refinery TAR, follow these steps for proper closeout:

- Inspection Reports: Ensure detailed inspection reports are created promptly, summarizing all key discovery items for each piece of equipment.

- FFS Reports: Fully document all FFS efforts performed during the TAR. Finalize reports within a few weeks post-TAR.

- Review of Findings: Compare TAR findings with previous corrosion studies, incident documentation, and prior run issues to identify recurring problems and assess mitigation effectiveness.

- Presentation and Communication: Present a summary of findings to stakeholders, highlighting key outcomes and sharing knowledge with the team.

- Verification of Inspection and Repair: Confirm that all equipment opened during the TAR was inspected per the worklist and that all identified issues have been addressed.

- Update RBI and Maintenance Plans: Incorporate TAR findings and lessons learned into the risk-based inspection (RBI) program, updating inspection intervals and maintenance plans as needed.

- Safety and Compliance Checks: Verify all safety procedures were followed and document any new recommendations for future TARs.

- Feedback: Solicit feedback from the TAR team and site contacts to identify challenges and suggestions for improvement.

- Final Closeout Meeting: Conduct a meeting with all relevant parties to review outcomes, discuss unresolved issues, and assign responsibility for follow-up actions.

By following these steps, you ensure a thorough and systematic closure of TAR activities, supporting both operational reliability and continuous improvement.

Please contact the authors with any questions by submitting the form below: