Introduction

Asset criticality can often be overlooked when developing reliability strategies and managing resources for equipment. For the most part, work gets done, equipment runs, and products are manufactured with the ongoing daily challenges that happen within a company. But when an asset fails, production stops, and the consequences of the failure are analyzed, we can be left wondering…

- How did this happen?

- How did we allow a delay to a key inspection?

- How was a repair not made in time to avoid a catastrophic failure?

- How did the new project allow for the same limits in reliability for the new equipment?

A well-planned and executed criticality assessment can provide clarity to what equipment is most critical to your organization’s risks and objectives. The assessment will provide a better cross-functional understanding of what impact each asset has to the business and will help prioritize resources and future activities to continuously improve plant performance and reduce risk.

This article will cover steps to prepare for performing a criticality assessment, selecting the assessment team, analyzing the results, and implementing activities that can leverage the value of the results.

Watch the “Asset Criticality” webinar presented by James R. Olson from January 20, 2022

Preparing for the Criticality Assessment

To perform a criticality assessment, some preparation is needed to ensure it meets the organization’s expectations. The business objectives and company risk tolerance, list of assets to be reviewed, and current risk assessment documents are all key information needed to perform an effective assessment. Additional information regarding the assets is also helpful to supplement the assessment team’s knowledge.

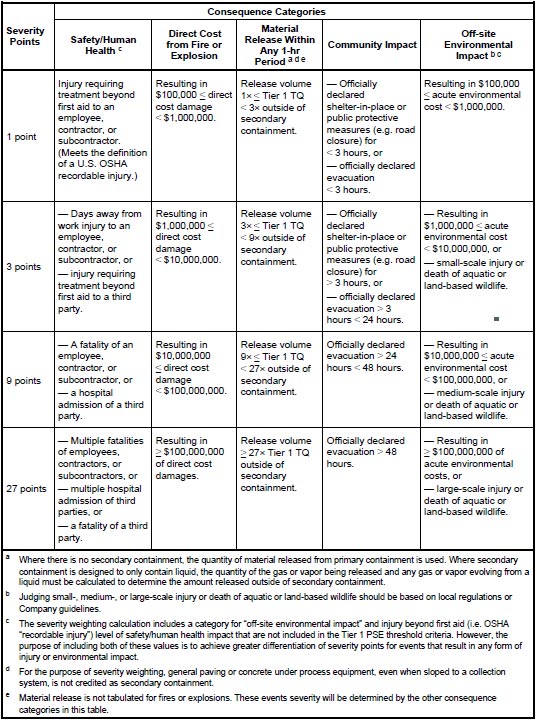

Begin preparation by identifying the business objectives for which performance of the assets needs to meet. This may include production rates, asset reliability and availability, product quality requirements, and costs of production. Additionally, the organization’s risk tolerance regarding health, safety, security, and environmental (HSSE) parameters needs to be identified. The categories for the business objectives and HSSE parameters should be organized in a table with thresholds of performance established according to the levels of acceptable risk to the organization. An example can be found in API RP 754, Table D.1.

Next, obtain a copy of the Master Asset List and organize the assets by system, and if possible, have the piping and instrumentation diagram (P&ID) number associated with the asset. This will help to facilitate the criticality assessment.

A review of risk assessments performed on the process will identify those assets where consequences of failure (COFs) have already been analyzed. Refer to hazard and operability (HAZOP) studies, layer of protection analysis (LOPA), and the safety requirement specification (SRS). Other documents may exist depending upon each organization’s policies and programs.

Additional information to aid the team performing the criticality assessment includes a set of the process flow diagrams (PFDs), P&IDs, maintenance work order history, and equipment files for the assets. Having this information on hand for the assessment team will help facilitate the assessment and can reduce the time to clarify questions and avoid follow-up actions.

With the documentation collected, an assessment tool will need to be set up to capture the results of the analysis and leverage the criticality data. There are several software tools available as stand-alone solutions and as parts of an enterprise solution. Often, a simple spreadsheet can be set up to perform the assessment with the assets listed and the categories for the business objectives and HSSE parameters in separate columns. An asset having a higher impact in the respective category will receive a higher score.

Assembling the Team

The team performing the criticality assessment should consist of a cross-functional group including operations, maintenance, engineering, and HSSE personnel. The experience level of each person should be such that they can answer how the failure of each asset will impact the business objectives related to their responsibilities. The operations representative should be qualified on the system under review, including knowledge of the operating procedures, upset conditions, how the process is controlled, and consequences of asset failures. The maintenance representative will need to have knowledge of the asset history, maintenance activities currently being performed, repair procedures, and spare parts. Engineering will need to have knowledge regarding the design of the asset and how the asset may fail, including the likelihood of failure. The HSSE representative will need to be able to assess the impact of asset failure with respect to the business objectives and regulatory thresholds. For some assets, it may be necessary to bring in an expert familiar with the details of the equipment. For example, this may be a rotating equipment expert for complex machinery systems or electrical engineer for electrical switchgear.

It is also important to include one individual to facilitate the assessment and another individual to capture the discussion and score the results. While it is possible for one person to complete these tasks, it is more efficient to have two people working together to maximize the use of the group’s time.

Assembling a group of this caliber takes commitment from their managers and likely will require a series of shorter sessions to avoid conflicts with other work priorities. Continuity of the group is important to ensure a consistent perspective throughout the assessment.

Performing the Assessment

Once the team members are identified and documentation is collected, set up a schedule for the review sessions. The amount of time required will depend on the experience level of the team and the amount of discussion necessary to establish a consensus of the impact each asset will have.

Review each asset with respect to the categories for business objectives and HSSE parameters, and record a score corresponding to the level of impact that failure of that asset will have. Combine the scores across the categories to get an overall composite criticality score for the asset.

There are a couple different approaches to assessing the level of impact an asset may have. A consequence-based approach will look at what happens when the asset fails. A risk-based approach will include the likelihood of the failure occurring. As an example, a pipe that contains a hazardous chemical, but has no damage mechanism present, would have a failure score lower than if only the failure of the pipe was considered.

Finally, a company directive regarding criticality may override the assessment process. One type of directive may be that all pressure relief devices are considered critical.

Analyzing the Results

After the assessment is complete, sort the assets by their composite criticality scores from the highest to the lowest. The top 10% to 20% should receive the designation of ‘Critical Asset.’ Other sub-classifications may be identified such as safety-critical, environmental-critical, quality-critical, etc. These sub-classifications can be helpful for prioritizing activities and communicating their importance to different departments.

Communication of the criticality results across the organization will help to ensure proper prioritization by the respective departments. Capturing the data in the computerized maintenance management system (CMMS) will help maintenance supervisors schedule and prioritize work such that delays are avoided for critical assets, effectively manage spare parts to reduce downtime, and justify reliability strategies and the necessary resources to manage the critical equipment.

Criticality also plays an important role in developing and optimizing the reliability strategy for an asset. It can help justify the need for a reliability-centered maintenance (RCM) analysis along with increased activities and resources for monitoring and inspecting the health of critical assets.

Capital projects can also use the criticality data when defining scope. Failure points should be eliminated and reliability improvements should be included when possible to help reduce risk of failure.

Root cause failure analysis (RCFA) investigations can also be prioritized according to an asset’s criticality level. This can help manage RCFA efforts to focus on the assets most impactful to the business.

The result of the assessment should be reviewed periodically to keep alignment with business objectives and HSSE parameters. In-service inspection results should also trigger a review of an asset’s criticality, and adjustments should be made accordingly. For example, if the corrosion rate increases or the material thickness will approach Tmin before the next scheduled inspection, the criticality may be increased until a resolution is reached.

Summary

Performing an asset criticality analysis is a crucial first step for establishing and improving a reliability program. With good preparation, the assessment will increase awareness of how important assets are and what impact they may have on the business and surrounding community. This will lead to effective prioritization of resources to improve asset performance and plant reliability, as well as reduce risk to the business.

For more information, submit the contact form below: