API RBI SOFTWARE

- Home

- Software & Technology

- API RBI

Optimize Inspection Plans

API RBI software is the industry’s only fully compliant API 581 calculator that helps you plan maintenance strategies efficiently and accurately. Use the power of API RBI on the desktop software to conduct quantitative risk-based inspection (RBI) studies that:

- Remove uncertainty

- Optimize inspection schedules

- Improve operational safety and reliability

- Identify areas of vulnerability

Cloud-Native End-to-End Lifecycle Management

Introducing PlantManager ASSET™, a cloud-native planning and inspection lifecycle operations technology that extends your ability to conduct RBI studies into a fully integrated asset integrity management system (AIMS).

PlantManager ASSET provides end-to-end asset lifecycle management capabilities by managing inspection activities, recording damage management locations (DMLs), and calculating fully quantitative API 581 risk assessments for inspection optimization.

Experience API RBI for yourself.

API RBI software supports successful quantitative risk-based inspection (RBI) studies by providing guidance for each component to account for applicable damage mechanisms and recommending an inspection plan, based on risk.

| Quantitative Approach (API 581) | Qualitative Approach |

|---|---|

| API RP 581 uses a quantitative approach to implementing RBI, accounting for the probability of failure (POF) and the consequence of failure (COF) for each piece of equipment in a process unit. | API RP 580 is a risk-based inspection (RBI) document that identifies the basic elements for developing, implementing, and maintaining an RBI program. |

Key Considerations:

|

Key Considerations:

|

| Choose API RBI software, the industry’s only API-branded RBI tool, as the foundation for all your quantitative RBI projects. API RBI is current to API 581 Edition 3 Addendum 2 and is also available in Spanish. |

Summary Report Sheets

Quickly and easily develop custom inspection reports to share information with other members of your team.

- Create or update reports to include custom content using Microsoft® Excel® templates

- Dynamically update and configure all the existing summaries in MS Excel

- Include custom content with the PlantManagerTM keywords report sheets

- Configure all labels, design, and formatting in MS Excel and utilize all the formatting options and macros

RiskBI — Data Visualization

Gain greater insight into your operations and performance and quickly identify trends and problem areas. RiskBI, using Microsoft® PowerBI, dynamically updates to help unit inspectors and corporate executives visualize inspections to support faster and more informed decision-making.

- Compare RBI assessments across several units in a facility to understand the differences and similarities between each unit

- Compare facilities’ corrosion rates and how they fall on the risk matrix,

- Identify when multiple equipment is due for inspection, which components are overdue, when equipment will hit minimum thickness, and how to reduce risk with inspections

Damage Mechanism Screening

Estimate your equipment’s susceptibility to the most common damage mechanisms in the refinery industry using the damage mechanism screening tool. This feature uses the damage solver, which is based on API 571, to:

- Filter potential damage mechanisms based on process unit, material of construction, temperature, damage source, and morphology

- Implement a damage screening assessment without relying on in-house materials and corrosion experts

- Assign corrosion rates and cracking susceptibilities based on the judgement of industry experts

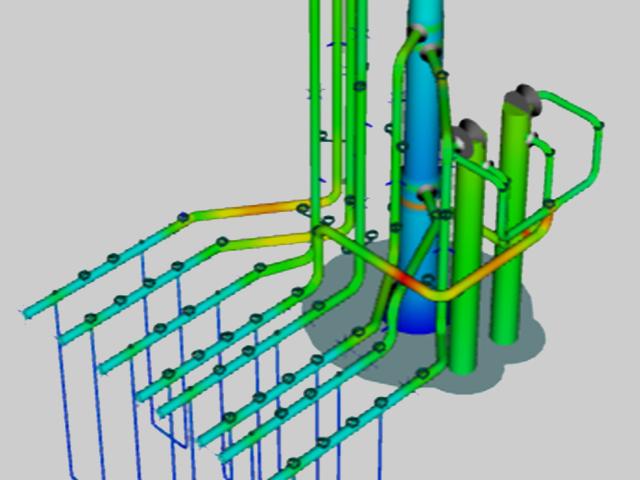

Inspection Planning

The inspection intervals methodology identifies the high- and low-risk equipment at a facility, allowing you to focus future inspections on the highest risk equipment to reduce costs and overall risk.

- Set a maximum interval and recommends re-evaluation of the RBI study at a minimum of every 10 years

- Calculations are not limited by or based on half-life calculations or prescriptive interval approaches

- Choose from multiple options for inspection effectiveness, including how much each option will reduce risk and effect on future target dates

- Select inspection target dates for each damage mechanism rather than the superposition method to calculate target dates

You will learn how to use API RBI software, including developing skills in navigation and application. The course helps you understand API RP 581 technology and how to interpret its calculated results to help develop an effective RBI program. This training course can be offered virtually or in-person and may be customized to meet your corporate objectives.

Recommended Reading

- Library /

- Risk-Based Inspection (RBI) /

- Library /

- Risk-Based Inspection (RBI) /

- Sound Bytes Articles /

Software Expertise

Equity’s proprietary software is built by industry experts and used by our consulting engineers on fitness-for-service (FFS), damage mechanism reviews, risk-based inspection (RBI) assessments and other asset lifecycle management projects. Equity software is updated frequently to meet the latest API and ASME codes and standards.

Our experts:

- Have 380+ years of combined experience

- Pioneered development of FFS and RBI

- Are the primary authors on WRC 528 and WRC 562

- Serve as lead investigators on API 579 and API 571

Recently Published Software Articles

Analysis of Piping Surge Events

Surge events in piping systems can lead to severe displacements, loud noises, and operational challenges. Using a case study, this article highlights the factors behind surge events, including rapid changes in liquid velocity and pressure, and how forces generated during these transient events can impact piping systems. The authors discuss how a few targeted support modifications effectively resolved these issues without resorting to costly system overhauls or potentially problematic specialty equipment.

SIMFLEX-IV: A Modern Pipe Stress Engineering Solution

SIMFLEX-IV, the latest update to E2G’s cloud-based piping stress analysis software, will help you prevent potential failures by improving the structural integrity of piping systems and supporting structures. In a single run, you will be able to assess sustained, occasional, and displacement stresses at every data point throughout the piping system. This article introduces you to fast and easy ways to integrate advanced static and dynamic piping stress analysis into your daily workflow.

Access the E2G Help Desk

E2G’s software support help desk is available from 8:00AM to 4:00PM Eastern time (-5 GMT).

Software clients will receive an initial response from the E2G Help Desk within one business day.