- Home

- 2025 Events

Equity Solves Industrial Asset Reliability Problems

Equity is committed to safety and reliability. Using our technology-forward mindset, we solve complex industrial asset integrity issues and improve plant performance. Our practical and actionable solutions help you manage risk, control costs, and maximize equipment lifecycle. Our specialized consulting services, technology, training, and corporate standards are dedicated to your safety and success.

Equity Engineering

Equity Engineering solves challenging industrial asset integrity problems. Our practical recommendations improve safety, increase equipment reliability, and mitigate risk across the asset lifecycle. Our specialized consulting services include mechanical and structural engineering, rotating equipment, vibration, instrumentation and controls, metallurgy and corrosion, and process technologies.

- Library /

- Midstream /

- Midstream & Pipelines /

- Oil & Gas /

- Pipeline /

- Library /

- Materials & Corrosion /

- Turnarounds /

- Ammonia /

- Ammonia & Fertilizer /

- Library /

- Mechanical & Structural Engineering /

- Risk-Based Inspection (RBI) /

- Tanks /

Using their industry experience, our ICE team applies a multi-disciplinary approach to support instrumentation and electrical system program improvements and modernization goals.

Our team of mechanical and structural engineers leverage their design and in-service expertise to ensure assets are safe to operate even with the presence of damage or defects.

Our team of corrosion and metallurgy experts combine their extensive experience with state-of-the-art technology to create safe operating environments.

Our pressure relief system (PRS) experts maintain safety critical PRS and develop practical mitigation strategies to meet risk management targets, compliance requirements, and business objectives.

Our team of vibration experts combines field testing, data analysis, and advanced computational analysis to provide practical and actionable recommendations to solve complex problems with rotating machinery, piping, and structures

CorrSolutions

CorrSolutions offers total asset support for all stages of an inspection and maintenance program. We develop tailored asset integrity strategies that achieve goals of increased operational efficiency, reduced downtime, and improved equipment reliability. Our solutions include circuitization, risk-based inspection, inspection and CML optimization, IDMS implementation, and advanced data analysis.

Achieve measurable benefits and new insights into corrosion management by applying the advanced thickness analysis methodology

Read how the Bayesian Optimized Asset Reliability (BOAR) assessment combines expert knowledge with inspection data to identify corrosion rates

Inspectioneering Journal article discussing advanced statistical analysis

Equity Software

Equity Software develops solutions that address the critical needs of the industrial processing industries and provides integrated, cloud-native products that deliver insights into all aspects of an asset’s lifecycle, giving you the confidence to effectively maintain and operate your equipment.

PlantManager 6.0 is a flexible and scalable cloud-native software platform that leverages the power of Equity Software’s suite of analytical tools to deliver insight into all aspects of an asset’s lifecycle

PlantManager ASSET provides end-to-end asset lifecycle management capabilities by managing inspection activities, recording damage management locations (DMLs), and calculating fully quantitative API 581 risk assessments for inspection optimization.

PlantManager SAGE is a collection of mechanical engineering modules for conducting comprehensive evaluation and analysis into the design, condition, and compliance of new and in-service equipment.

With more than 50 tools, the cloud-native eec platform helps you make effective and informed decisions to keep your facilities operating safely and reliably.

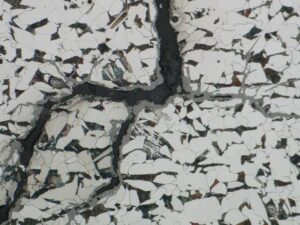

Corrosion under insulation (CUI) is one of the most nuisance damage mechanisms in refining, petrochemical, chemical, and many other industries.

Equity Engineering Practices (EEPs)

The Equity Engineering Practices (EEPs) are the industry’s most comprehensive and commercially available engineering standards. The EEPs combine regulatory requirements with legacy documents, lessons learned, operating experiences, and subject matter expertise to enhance mechanical integrity programs, improve equipment availability, and reduce inspection and maintenance costs.

The EEPs are a collection of detailed and customizable best practices to satisfy process safety management (PSM) requirements, accessible via a cloud-native platform.

The Re-Use collection supports owner-users evaluating how to repurpose or reuse equipment for new conditions, renewable fuels, and biodiesel.

Take this quick test to find out how your organization’s engineering standards compare to the industry’s most comprehensive Best Practices.

Equity Technical Institute (ETI)

Equity Technical Institute (ETI) is committed to developing and delivering hands-on and relevant training for industrial processing and manufacturing professionals. ETI uses industry knowledge and expertise to develop high-quality specialized courses. ETI is recognized as an API-U preferred provider. ETI offers 4 delivery options – hybrid, virtual, on-site, or on-demand – to support all learning styles.

- Library /

- Training /

- Library /

- Training /

- Library /

- Training /

- Corporate Overview /

- Library /

- Training /

- Equity Engineering Practices (EEPs) /

- Industry Insights /

- Library /

- Mechanical Integrity /

- Training /