PLANTMANAGER

Cradle-to-Grave Asset Lifecycle Management Platform

PlantManager is a flexible and scalable software platform that leverages the power of Equity’s suite of analytical tools to deliver insight into all aspects of an asset’s lifecycle. PlantManager will give you the confidence to solve specific asset management challenges and turn inputs into insights.

- Quickly identify issues

- Reduce time spent maintaining all equipment or components

- Eliminate duplicate or multiple software products

- Combine advanced analysis with comprehensive RBI and fitness-for-service tools

Contact Equity Software Experts

PlantManager

PlantManager uniquely offers both inspection planning and management tools and advanced engineering analysis calculators to give you the ability to conduct comprehensive analyses of an asset’s integrity and performance.

As a cloud-native platform, PlantManager delivers customizable, flexible, and scalable solutions to meet the dynamic needs of you and your facility.

With PlantManager, you will:

- Develop fit-for-purpose inspection plans to reduce costs and minimize maintenance time.

- Improve facility-wide communication, data analysis, inspection planning, and maintenance strategies.

- Access the industry’s most comprehensive collection of material codes and standards.

PlantManager ASSET

Achieve end-to-end asset lifecycle management capabilities by recording damage management locations (DMLs), managing inspection activities, and calculating fully quantitative API 581 risk assessments for inspection optimization.

PlantManager SAGE

Analyze assets with a collection of mechanical engineering modules for conducting comprehensive evaluation and analysis into the design, condition, and compliance of new and in-service equipment.

What is an IDMS?

An inspection data management system (IDMS) is an essential software tool for companies focused on proactive asset lifecycle management. Choosing the right IDMS for your facility will help you to improve asset reliability, reduce the risk of equipment failure, and optimize maintenance activities.

With so many IDMS options available, how do you choose the right software platform for your plant?

- Customizable & Scalable: Implement modular, cloud-native software tools that allow facilities to add or subtract functionality based upon need.

- Data & Document Management: Catalog inspection, design and engineering documentation, and reliability data to easily access mechanical integrity documents and asset records.

- Integrated: Initiate fitness-for-service (FFS), risk-based inspection (RBI), and other integrity analyses directly from inspection results.

- Cloud-native: Achieve faster calculations using superior performance hardware and always have access to the latest software updates.

- Reporting & Activity Management: Monitor and analyze inspection activities for timely equipment delivery and issue escalation.

- Secure: Use software that is certified to ISO 9001:2015 quality standard and SOC1 compliance.

Inspection Planning & Management: PlantManager ASSET

PlantManager ASSET is a cloud-native planning and inspection lifecycle operations technology that will disrupt the traditional IDMS space. PlantManager ASSET provides end-to-end asset lifecycle management capabilities by managing inspection activities, recording damage management locations (DMLs), and calculating fully quantitative API 581 risk assessments for inspection optimization.

PlantManager ASSET delivers:

- Tools to comply with OSHA process safety management (PSM) standards and industry inspection standards (API 510, 570, and 653)

- Risk-based inspection (RBI) calculations

- Enhanced corrosion analysis technology

- Advanced analysis for fitness-for-service (FFS) assessments

Two Methods for Managing Damage

PlantManager ASSET incorporates unique functionality that enables companies to easily monitor and manage existing damage such as thinning or cracking and proactively observe and mitigate potential damage.

Depending on your needs, you can choose either the damage monitoring location (DML) or condition monitoring location (CML) workflows.

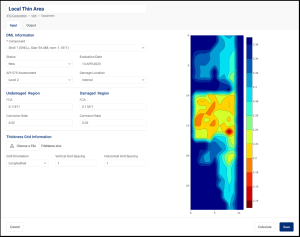

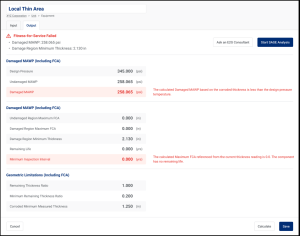

Damage Management Location (DML)

DMLs are the regions on a component that are identified to have active damage or defects that require a fitness-for-service (FFS) evaluation.

PlantManager ASSET uses a proprietary workflow to automate and guide the appropriate damage data collection and seamlessly incorporate FFS calculations using PlantManager SAGE.

Benefit:

- Guide the damage data collection process

- Incorporate FFS calculations

- Make accurate & timely engineering decisions

Condition Monitoring Location (CML)

CMLs are specific locations on pressure vessels and piping where monitoring is conducted to observe potential damage and corrosion.

PlantManager ASSET uses the patented CorrSolutions Bayesian optimized asset reliability (BOAR) methodology to provide better and more predictive CML results

Benefit:

- Quality check circuitization

- Quantify localized and generalized corrosion

- Apply informed corrosion rates to RBI program

Features & Functionality

Asset Management

- Manage the complete asset hierarchy

- Support code and design calculations

- Easily access mechanical integrity documents and asset records

Data & Document Management

- Catalog multiple types of inspection data

- Apply industry standard & proprietary analysis methods

- Monitor remaining life of integrity critical assets

- Catalog inspection documents, design and engineering documentation, pictures, and CAD files

Planning & Scheduling

- Configurable inspection scheduling across all support assets

Reporting & Activity Management

- Customizable inspection checklist

- Facilitate and monitor inspection activities for equipment and components

- Implement appropriate maintenance and issue escalation strategies

Finding & Consideration Management

- Catalog integrity and reliability concerns

- Achieve long-term transparency

Advanced Engineering Analysis: PlantManager SAGE

PlantManager SAGE is a collection of mechanical engineering modules for conducting comprehensive evaluation and analysis into the design, condition, and compliance of new and in-service equipment.

This cloud-native software incorporates the latest API 579-1/ASME FFS-1 standards to deliver new and alternative analytical procedures to facilitate fitness-for-service (FFS) analysis and remaining life assessment of in-service equipment.

PlantManager SAGE leverages SagePlus™ behind the scenes to deliver accurate FFS assessment results quickly and easily. Additional PlantManager SAGE functionality will be available soon. If you’d like a demo of the new capabilities, please fill in the form at the top of the page.

Why Choose PlantManager?

PlantManager is the cumulation of more than 20 years of engineering knowledge and expertise. We have taken the advanced functionalities available in our desktop software and transformed it into the new cloud-native PlantManager platform. We have combined our mechanical engineering capabilities with strong design competencies into an accurate, integrated, and secure asset integrity management program.

Access the Equity Help Desk

Equity’s software support help desk is available from 8:00AM to 4:00PM Eastern time (-5 GMT).

Software clients will receive an initial response from the Equity Help Desk within one business day.

Recommended Reading

- Library /

- SAAS /

- Software /

- Library /

- SAAS /

- SagePlus /

- Library /

- SAAS /

- Software /

- Library /

- SAAS /

- Software /

Software Expertise

Equity’s proprietary software is built by industry experts and used by our consulting engineers on fitness-for-service (FFS), damage mechanism reviews, risk-based inspection (RBI) assessments and other asset lifecycle management projects. Equity software is updated frequently to meet the latest API and ASME codes and standards.

Our experts:

- Have 380+ years of combined experience

- Pioneered development of FFS and RBI

- Are the primary authors on WRC 528 and WRC 562

- Serve as lead investigators on API 579 and API 571