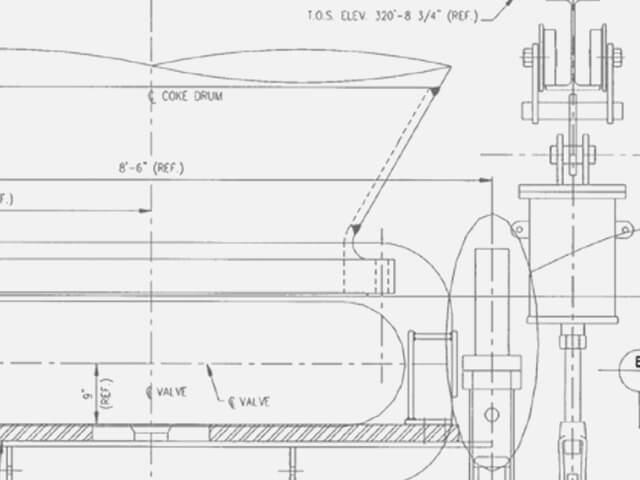

Leveraging Advanced Analysis for Coke Drum Reliability

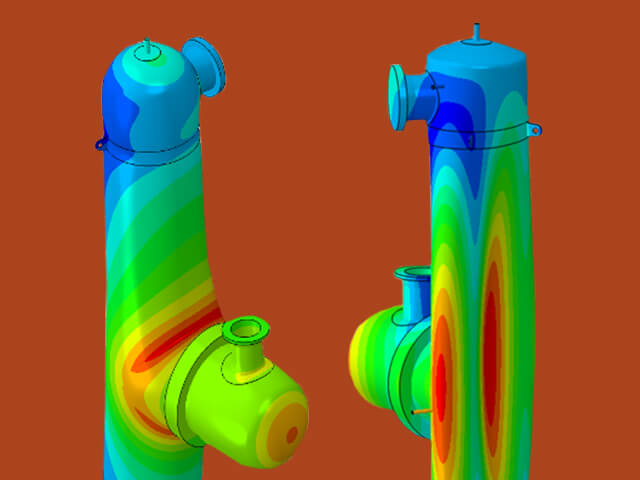

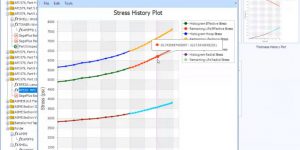

Coke drums in delayed coker units present many reliability problems because they are subjected to unique types of damage mechanisms due to their operation. Thermal fatigue cracking is common in regions of high thermal stress due to frequent and severe thermal cycling. Bulging is also common because of this severe thermal cycling that creates hot and cold spots due to channeling effects in the coke formation that results in thermal ratcheting or progressive cyclic plastic strain accumulation.