Effect of Sigma Phase on FCC internals

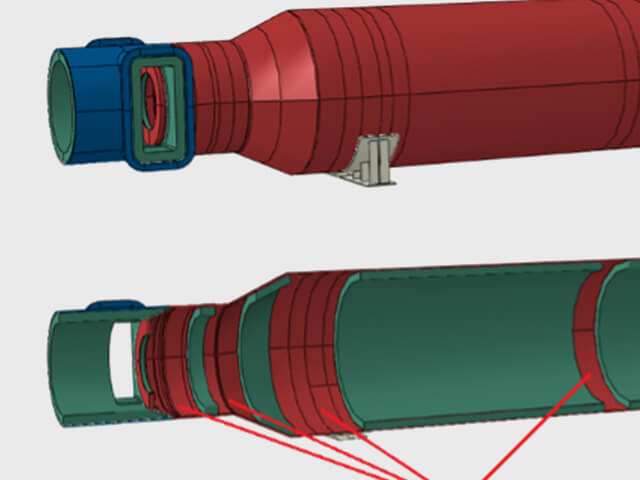

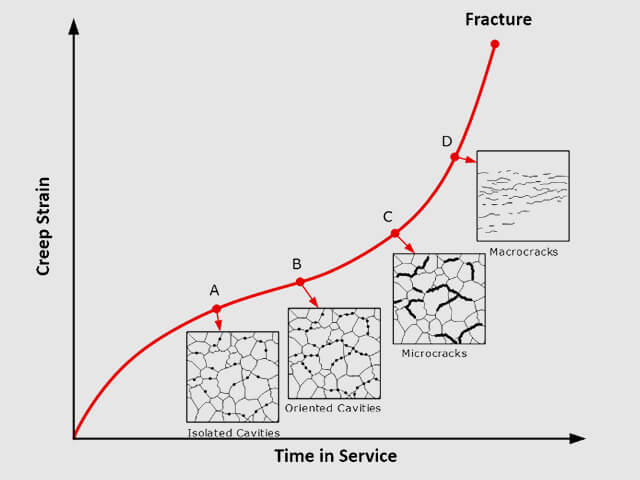

Sigma phase embrittlement is a concern for austenitic stainless-steel components in FCC units and other internal welds in FCC regenerators. Prolonged exposure to high temperatures can lead to sigma phase formation, reducing toughness and ductility and increasing the risk of creep cracking. In this article, the authors explore preventive measures to mitigate sigma phase formation and the importance of weldability testing to increase the reliability of FCC units.