Advancements in Risk-Based Inspection Strategies for Ammonia Storage Tanks

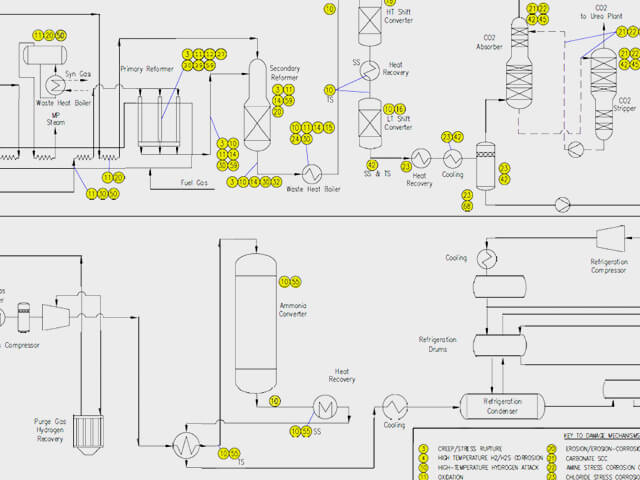

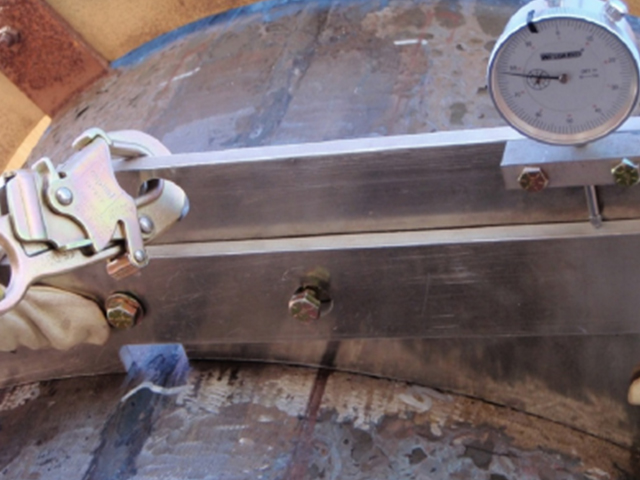

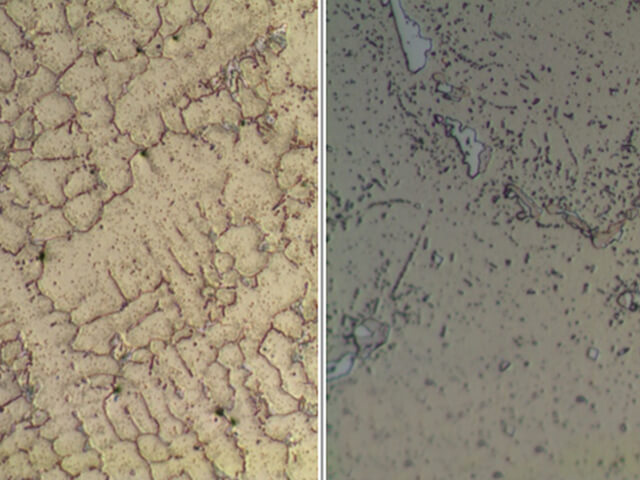

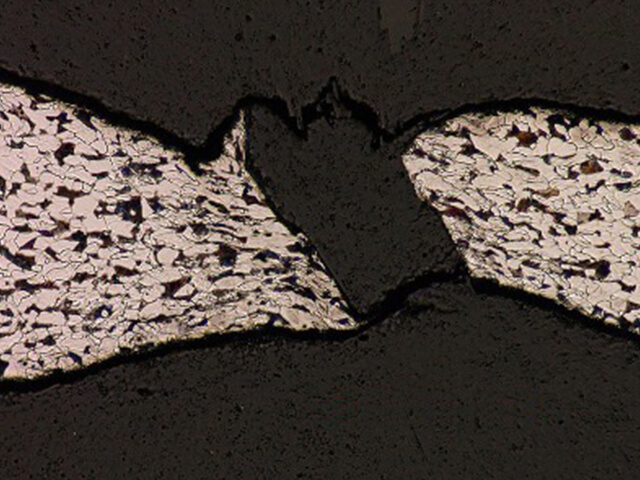

Developing a repeatable, in-service inspection strategy for ammonia storage tanks is difficult; however, it will help improve operational reliability and minimize the probability of failure from several damage mechanisms, including ammonia stress corrosion cracking (SCC). In this article, the authors discuss Equity’s multi-disciplinary approach to navigate the challenges of these high-consequence ammonia storage tanks. Read how we integrate risk-based inspection (RBI), fitness-for-service (FFS), and materials and corrosion expertise to provide a comprehensive and practical inspection strategy.