Hot Tap Evaluations and Practical Guidance for In-Service Repair Welding

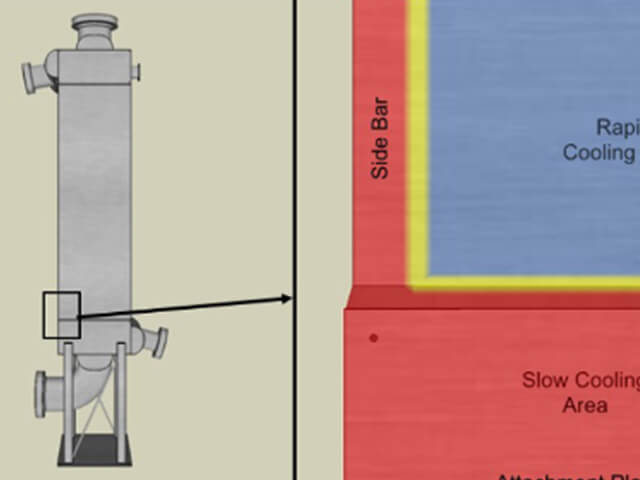

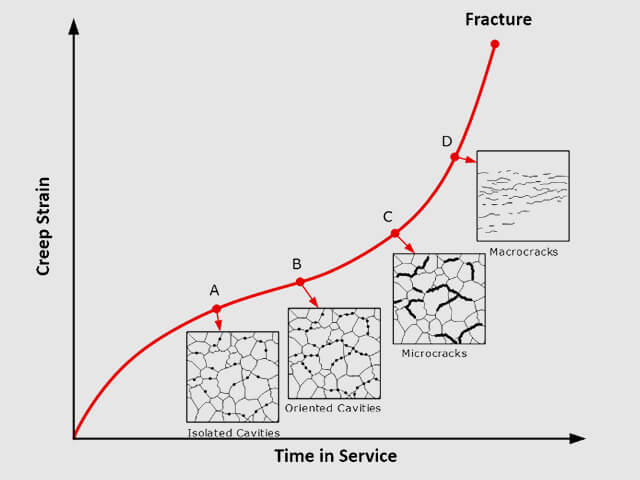

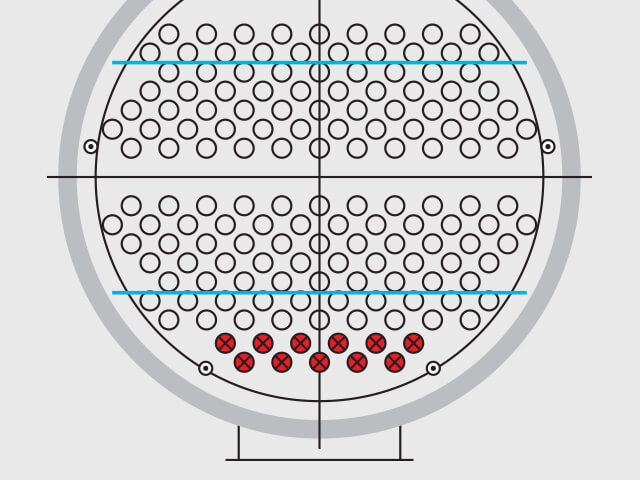

In-service welding as part of a maintenance program is a practical and economical way to address leak repairs or new nozzle installations; however, it does come with a few risks, including burn-through and hydrogen-induced cracking. In this article, Raj will discuss the risks involved with in-service welding, thermal analysis to quantify the risks, and practical in-service welding considerations to ensure safe and successful hot tap connections.