Two-Phase Flow Piping Vibration

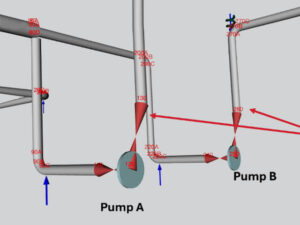

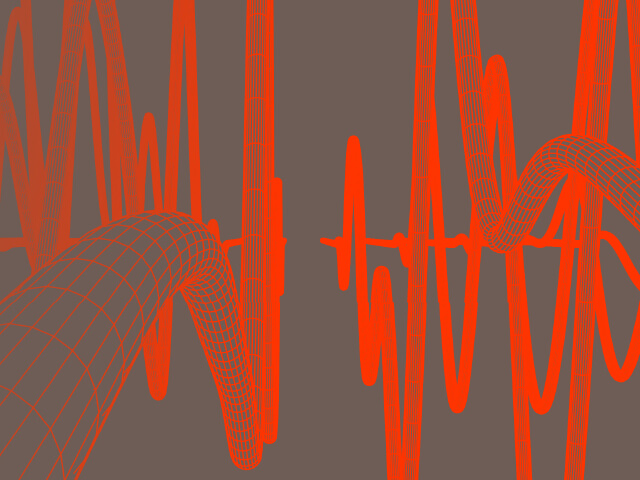

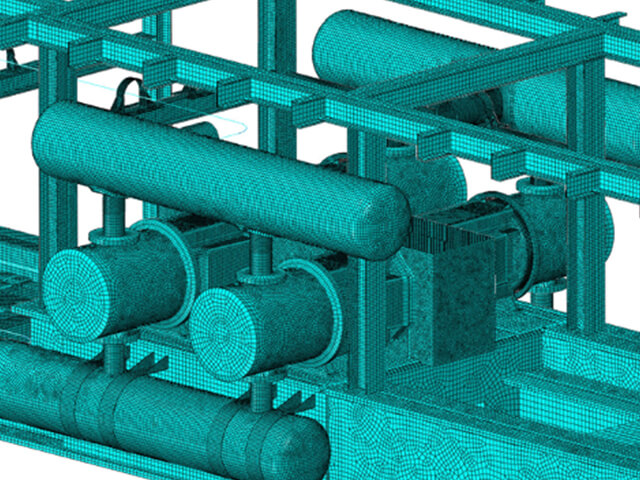

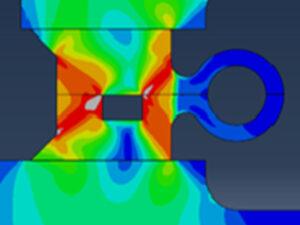

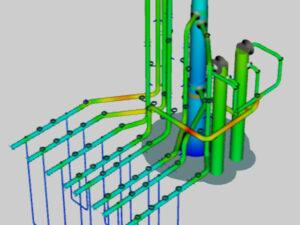

Two-phase flow creates complex dynamic forces that can lead to catastrophic fatigue failure, yet traditional restraints often clash with high-temperature thermal expansion needs. This article explores how to diagnose flow regimes and use advanced metrics like kurtosis to design effective, thermally safe remediation strategies.